Making a Loose Fitting Rivet

With The

FrankenRiveter

(named after Frankenstein's Monster)

Copyright 2012 by James P. Riser

For a special product that I manufacture I needed to

have a movable riveted joint between a number of parts. To complicate

matters, the rivet head needed to be within a 1/8" recess.

An orbital riveter sounded like the right machine for

the task at hand. After getting sticker shock from seeing the

prices of new machines, I went looking for a used one in semi-servicable

condition.

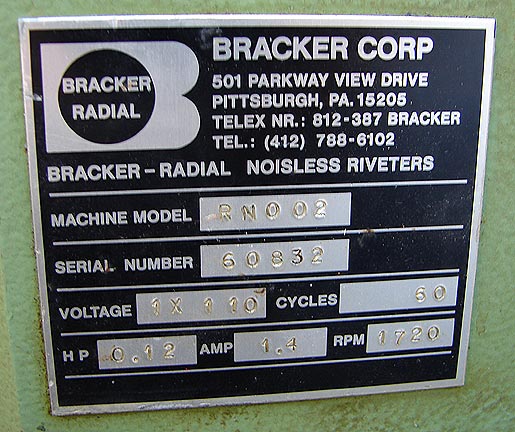

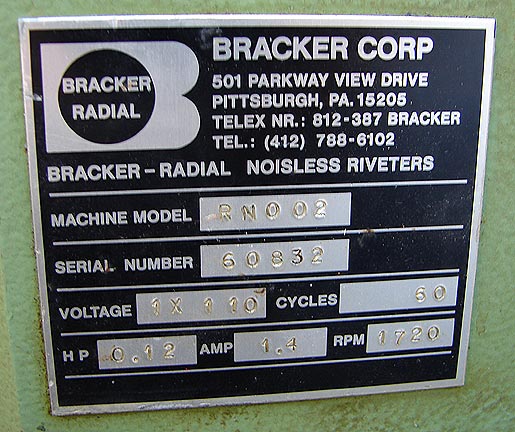

Living for business gambles, I bought the following

machine untested and unseen.

This is the unit

that I decided upon purchasing.

It came with the controller.

This is the unit

that I decided upon purchasing.

It came with the controller.  It turned out that the controller worked but the riveter

had leaking gaskets inside and the up/down movement by air pressure

was not reliable (jerky movement).

Since it arrived in this crate, problems should not

have come as a surprise.

It turned out that the controller worked but the riveter

had leaking gaskets inside and the up/down movement by air pressure

was not reliable (jerky movement).

Since it arrived in this crate, problems should not

have come as a surprise.

Fortunately, I can fix or devise a work-around for

most problems with machinery.

Fortunately, I can fix or devise a work-around for

most problems with machinery.

I think the machine

was made in France.

I decided to remove the head unit from its base and

adapt an old Gorton 3U pantograph base to work with the riveter.

After removing lots of rust from the base sitting outside in the

weather for years, I was able to get the table to move again as

I needed it to do.

I think the machine

was made in France.

I decided to remove the head unit from its base and

adapt an old Gorton 3U pantograph base to work with the riveter.

After removing lots of rust from the base sitting outside in the

weather for years, I was able to get the table to move again as

I needed it to do.

Here is the finished

FrankenRiveter on its now wheeled base. This outfit is heavy and

solid!

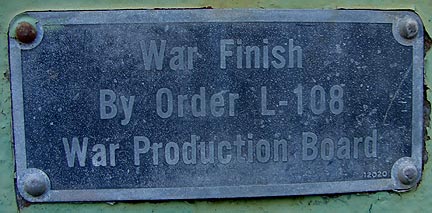

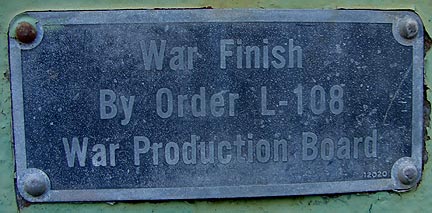

I decided to keep the old "War Finish" paint

on the Gorton base even though it was in bad shape.

Here is the finished

FrankenRiveter on its now wheeled base. This outfit is heavy and

solid!

I decided to keep the old "War Finish" paint

on the Gorton base even though it was in bad shape.  On the vise are the two parts to be test riveted -

a brass rod and a square aluminum bar.

On the vise are the two parts to be test riveted -

a brass rod and a square aluminum bar.

These are the items

to be riveted so that the brass bar can still move.

Before showing the result I will show a few closeups

of the action.

The custom trial tooling was made from oil hardening

tool steel. Barely showing here is a 6 degree taper on the tip

and its concave end. The tooling merely slips in to the machine

and is held in place by an internal magnet. In use the riveter

slowly forms the rivet end into a domed mushroom shape without

thickening the rod where it passes through the aluminum. Impact

riveting will not work for this job.

These are the items

to be riveted so that the brass bar can still move.

Before showing the result I will show a few closeups

of the action.

The custom trial tooling was made from oil hardening

tool steel. Barely showing here is a 6 degree taper on the tip

and its concave end. The tooling merely slips in to the machine

and is held in place by an internal magnet. In use the riveter

slowly forms the rivet end into a domed mushroom shape without

thickening the rod where it passes through the aluminum. Impact

riveting will not work for this job.

Using the old Gorton base crank, I raise the items

up to the spinning tool. The tool does not merely spin but is

at an angle and orbits the very tip (tooling length is critical).

With a little pressure the rivet head is formed.

Using the old Gorton base crank, I raise the items

up to the spinning tool. The tool does not merely spin but is

at an angle and orbits the very tip (tooling length is critical).

With a little pressure the rivet head is formed.

One of the characteristics of this item that I manufacture

is the deep recess for the riveted ends. Other makers do not do

this.

One of the characteristics of this item that I manufacture

is the deep recess for the riveted ends. Other makers do not do

this.

Here is the finished product - a perfectly formed loose

rivet head.

Here is the finished product - a perfectly formed loose

rivet head.  After this initial success, I made 4 new snap peens

(final tooling) to plug into the machine as needed for

other jobs. The job at hand dictates the shape and size of the

tooling.

After this initial success, I made 4 new snap peens

(final tooling) to plug into the machine as needed for

other jobs. The job at hand dictates the shape and size of the

tooling.

Here

they are after heat treating.

One of the new snap peens in the machine ready to go.

Here

they are after heat treating.

One of the new snap peens in the machine ready to go.

Below can be seen three bars already riveted and one

bar end ready for the rivet head to be formed. These bars are

only 1/16" in diameter.

Below can be seen three bars already riveted and one

bar end ready for the rivet head to be formed. These bars are

only 1/16" in diameter.

Several riveted

bars may be seen here.

Though the orbital riveter was designed for air pressure

control, it works perfectly for my needs under manual control.

The bars shown above were hardened brass. The FrankenRiveter works

equally well on stainless steel bar ends. This piece of junk has

actually turned out to be a nice tool.

Several riveted

bars may be seen here.

Though the orbital riveter was designed for air pressure

control, it works perfectly for my needs under manual control.

The bars shown above were hardened brass. The FrankenRiveter works

equally well on stainless steel bar ends. This piece of junk has

actually turned out to be a nice tool.

This is the unit

that I decided upon purchasing.

This is the unit

that I decided upon purchasing.

I think the machine

was made in France.

I think the machine

was made in France. Here is the finished

FrankenRiveter on its now wheeled base. This outfit is heavy and

solid!

Here is the finished

FrankenRiveter on its now wheeled base. This outfit is heavy and

solid!

These are the items

to be riveted so that the brass bar can still move.

These are the items

to be riveted so that the brass bar can still move.

Here

they are after heat treating.

Here

they are after heat treating.

Several riveted

bars may be seen here.

Several riveted

bars may be seen here.