Making a Spring Powered Motor - Page 2

Copyright 2008 by James

P. Riser

The first step in getting ready is to gather up some required

materials.

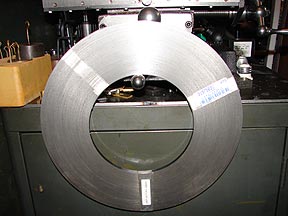

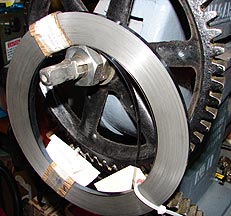

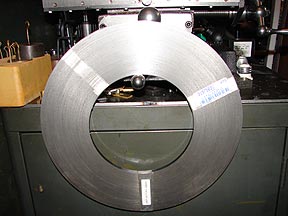

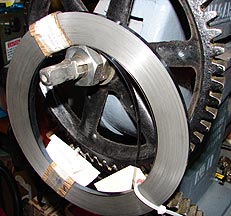

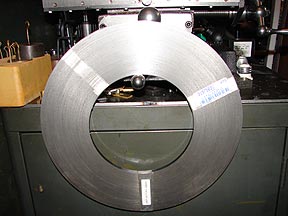

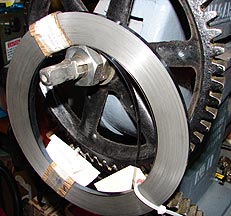

I already have a good assortment of spring steel for the motor.

These coils are left overs from previous jobs and my R&D supply:

I have brass sheet in many thicknesses plus brass bar

stock up to 4" in diameter. I can saw discs from the bars

to get any desired gear thickness. With my circle shear I can

cut gears any size from up to .080" thick. And with my big

punch I can easily punch out gear blanks up to 1/8" thick.

I am in good shape for raw materials.

Here are a couple sizes of punched brass gear blanks.

I have a very few Thornton wheel cutters; but need

more and several pinion cutters of appropriate sizes. So .. I

shall make my own as the "real cutters" are too expensive

for me. Being able to make my own tooling is very handy. The commercial

cutters start at $90 each! Below are shown clock cutters on the

left. This is the size of cutters that I will be making. On the

right are shown the clock cutters with watch cutters for a size

comparison.

The cutters that I will be making are 4 toothed cutters.

I decided to make my wheel and pinion cutters from

1" diameter A-2 air hardening tool steel.

Here is an assortment of A-2 drill rod that I will

be using for this project.

The cutters that I will be making are 4 toothed cutters.

I decided to make my wheel and pinion cutters from

1" diameter A-2 air hardening tool steel.

Here is an assortment of A-2 drill rod that I will

be using for this project.  The cutters that I will be making are cut from 1"

diameter A-2.

The cutters that I will be making are cut from 1"

diameter A-2.

The steel discs

were cut on my bandsaw.

The steel discs

were cut on my bandsaw.

This left burs

on the edge.

This left burs

on the edge. The wheels were cleaned up quickly on my belt grinder.

The wheels were cleaned up quickly on my belt grinder.

The next step was to convert these discs into wheels

having parallel sides and a properly sized arbor hole to fit my

machines.

The next step was to convert these discs into wheels

having parallel sides and a properly sized arbor hole to fit my

machines.

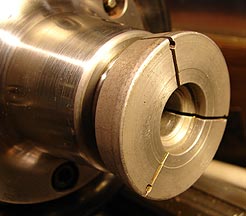

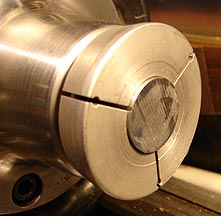

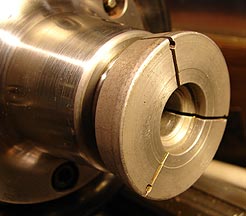

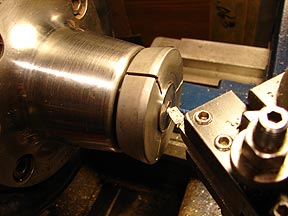

A pot chuck was

machined to hold the discs for shaping.

A pot chuck was

machined to hold the discs for shaping.

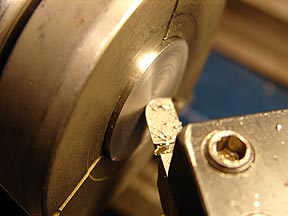

The first side

was smoothed up.

The first side

was smoothed up.  A center drill was used to start the arbor hole.

A center drill was used to start the arbor hole.

Several twist drills

were used to work up to the required hole diameter.

The Edge of the hole was beveled with the center drill.

Several twist drills

were used to work up to the required hole diameter.

The Edge of the hole was beveled with the center drill.

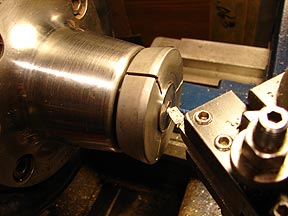

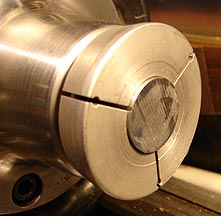

The

disc was removed from the chuck, turned over and the back side

cleaned up and beveled.

The finished disc looked like this.

The

disc was removed from the chuck, turned over and the back side

cleaned up and beveled.

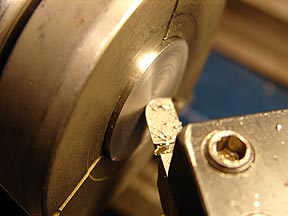

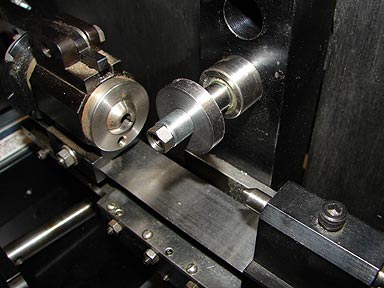

The finished disc looked like this.  Before working on the rest of the wheel and pinion

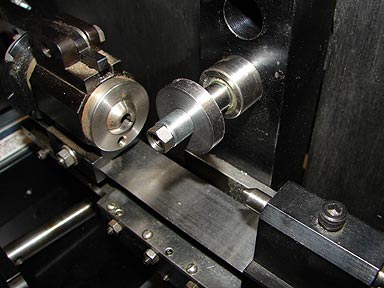

cutter blanks, I thought it a good idea to check the fit on my

pinion mill.

Before working on the rest of the wheel and pinion

cutter blanks, I thought it a good idea to check the fit on my

pinion mill.

Perfect fit and

it runs true!

I'll continue with things after I have machined all

21 of the cutter blanks.

Well, all 21 discs are arbor hole drilled and ready

for the next step.

Perfect fit and

it runs true!

I'll continue with things after I have machined all

21 of the cutter blanks.

Well, all 21 discs are arbor hole drilled and ready

for the next step.  Before I can continue with this project, I need to

machine the special holder for turning the required relieved teeth.

The metal for this is cut and I have picked up the required 7mm

- 1 tap for the arbor hole mounting bolt, as well as, the needed

dowel pin.

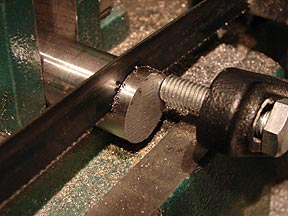

Before I can continue with this project, I need to

machine the special holder for turning the required relieved teeth.

The metal for this is cut and I have picked up the required 7mm

- 1 tap for the arbor hole mounting bolt, as well as, the needed

dowel pin.

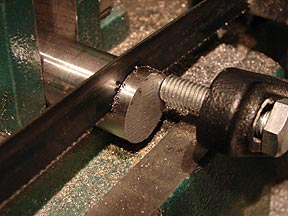

This 1" diameter

by 3" long A-2 rod will become the cutter holder for machining

the cutters.

More as I find time.

This 1" diameter

by 3" long A-2 rod will become the cutter holder for machining

the cutters.

More as I find time.

The steel discs

were cut on my bandsaw.

The steel discs

were cut on my bandsaw. This left burs

on the edge.

This left burs

on the edge.

A pot chuck was

machined to hold the discs for shaping.

A pot chuck was

machined to hold the discs for shaping. The first side

was smoothed up.

The first side

was smoothed up.

Several twist drills

were used to work up to the required hole diameter.

Several twist drills

were used to work up to the required hole diameter.

The

disc was removed from the chuck, turned over and the back side

cleaned up and beveled.

The

disc was removed from the chuck, turned over and the back side

cleaned up and beveled.

Perfect fit and

it runs true!

Perfect fit and

it runs true!

This 1" diameter

by 3" long A-2 rod will become the cutter holder for machining

the cutters.

This 1" diameter

by 3" long A-2 rod will become the cutter holder for machining

the cutters.