Bringing An Old Hardinge HC (Chucker) Back To Life

Copyright 2010 by James P. Riser

I decided to buy and bring this old lathe back to life

to manufacture two items that I have held off on due to lack of

the proper machine for the job. After some extensive remodeling,

this old chucker will do the jobs nicely.

When I bought the lathe, I was informed that it did

run - several years ago and that the power feed motor was burnt

out. I decided to take a chance on it. The machine had sit around

for a number of years and was rather dirty.

The lathe was loaded onto my trailer for the ride home.

Removing heavy machines from my trailer is always a

fun activity - one done slowly and carefully. I use my engine

hoist and steel cables.

Notice that the lathe is supported by steel bars under

the ends of the chip tray - not by the headstock nor bed.

I slowly lowered the lathe on to the legs of the hoist

to support it while I drilled the steel base to accept axles for

moving the machine.

I slowly lowered the lathe on to the legs of the hoist

to support it while I drilled the steel base to accept axles for

moving the machine.

Here are the wheels temporarily mounted on the machine.

Here are the wheels temporarily mounted on the machine.

The lathe came with the tooling shown below. All I

will require will be an assortment of Hardinge HC tool holders.

Here is the limited

turret tooling that came with the lathe. This is an 8 position

turret.

Here is the limited

turret tooling that came with the lathe. This is an 8 position

turret.

A very different speed adjustment ...

This plate is on the inside of the motor compartment

door. Two cams needed to be set and locked in position to adjust

speed ranges. By shifting a lever topside, the three speed ranges

would be changed as programmed by the cams.

These are the two adjustment cams with the locking

ring on the left.

These are the two adjustment cams with the locking

ring on the left.

Disassembly has

started.

Disassembly has

started.

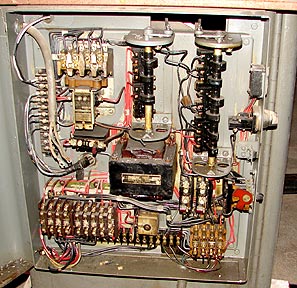

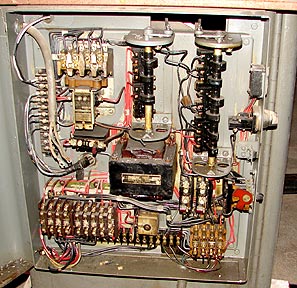

This is the wiring setup for the

lathe. Speed control wires had been disconnected.

The rear of the speed control looked like this.

This is the wiring setup for the

lathe. Speed control wires had been disconnected.

The rear of the speed control looked like this.

Here is another

view. Notice that the belt is missing teeth!

I decided to bypass all of the electrics and hook up

a new VFD directly to the high speed side of the motor windings.

Here is another

view. Notice that the belt is missing teeth!

I decided to bypass all of the electrics and hook up

a new VFD directly to the high speed side of the motor windings.

On the left is testing for motor rotation direction.

On the right is the completed wiring through

the side of the electrical box.

I utilized some now unused terminal strip

for connecting the VFD wires.

On the left is testing for motor rotation direction.

On the right is the completed wiring through

the side of the electrical box.

I utilized some now unused terminal strip

for connecting the VFD wires.

Here is the disassembled and removed speed control

with its motor.

It turns out that the motor windings are burnt out

- probably why all of the wires had been disconnected.

I'll replace this unit as stripped down

to control the variable speed belt mechanism.

This is what the speed control will look like. Since

with the VFD I will very seldom change belt ratios, I have decided

to make it all manual for the adjustment. A pulley has been installed

to serve as a temporary handwheel for testing. This will work

fine for the limited adjusting I will require on the projects

in mind for this lathe.

Here is the disassembled and removed speed control

with its motor.

It turns out that the motor windings are burnt out

- probably why all of the wires had been disconnected.

I'll replace this unit as stripped down

to control the variable speed belt mechanism.

This is what the speed control will look like. Since

with the VFD I will very seldom change belt ratios, I have decided

to make it all manual for the adjustment. A pulley has been installed

to serve as a temporary handwheel for testing. This will work

fine for the limited adjusting I will require on the projects

in mind for this lathe.

As you can see, the burnt out motor, the cam system,

and all unneeded parts have been removed.

Here is the lathe with the variable pulley unit just

tied in the high speed position.

As you can see, the burnt out motor, the cam system,

and all unneeded parts have been removed.

Here is the lathe with the variable pulley unit just

tied in the high speed position.

Here is the speed

adjustment with the new belts. All works fine.

Here is the speed

adjustment with the new belts. All works fine.

A previous owner

added a block of nylon.

A previous owner

added a block of nylon.  This nylon block was added to hold the pulley in position.

Adjusting the motor mounts should fix the drifting pulley problem.

In preparation for the new belt set, the old ones are

removed. The secondary belt comes out throught the end of the

headstock.

This nylon block was added to hold the pulley in position.

Adjusting the motor mounts should fix the drifting pulley problem.

In preparation for the new belt set, the old ones are

removed. The secondary belt comes out throught the end of the

headstock.

This is the VFD I used.

This is the VFD I used.

It is mounted as so.

It is mounted as so.  With this VFD unit I can adjust the lathe from just

ticking over for threading operations to 3000 rpm for finishing

work. Nice!

With this VFD unit I can adjust the lathe from just

ticking over for threading operations to 3000 rpm for finishing

work. Nice!

I was able to get

the power feed working again.

The coolant sump was cleaned and will get drain plumbing

installed.

I was able to get

the power feed working again.

The coolant sump was cleaned and will get drain plumbing

installed.

I cleaned the coolant

pump. It works and will get remounted with the screen filter.

The coolant pump has been rewired and remounted. Here

is the new drain line with valve for the coolant sump.

I cleaned the coolant

pump. It works and will get remounted with the screen filter.

The coolant pump has been rewired and remounted. Here

is the new drain line with valve for the coolant sump.

The belts were in horrible shape and new ones have

been installed.

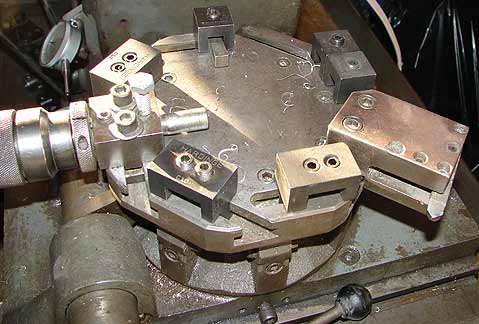

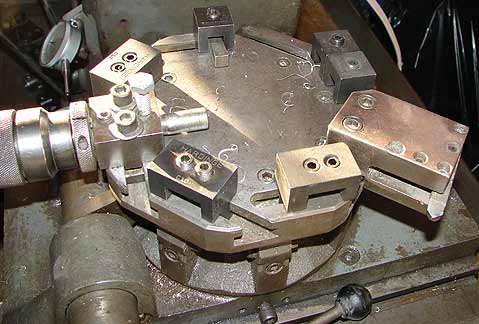

Here are the turret tool holders. Since any one setup

might require duplicate types of holders, you will see multiples

of useful holders.

The belts were in horrible shape and new ones have

been installed.

Here are the turret tool holders. Since any one setup

might require duplicate types of holders, you will see multiples

of useful holders.

This is an assortment

mounted on the turret.

This is an assortment

mounted on the turret.

These hold 1 or

2 (3/8") lathe tools.

Here you can see the bottom of a 5/8" holder and

a single tool holder.

These hold 1 or

2 (3/8") lathe tools.

Here you can see the bottom of a 5/8" holder and

a single tool holder.

This is how the

5/8" holders hook over the turret edge for accuracy.

The two set screws hold separate lathe tools for multiple

cuts.

This is how the

5/8" holders hook over the turret edge for accuracy.

The two set screws hold separate lathe tools for multiple

cuts.

This offset holder

allows machining from the side.

There is no point in having a lathe like this without

proper tooling. Here is a selection that I have available for

making my products. These all plug into the turret tool holders.

This offset holder

allows machining from the side.

There is no point in having a lathe like this without

proper tooling. Here is a selection that I have available for

making my products. These all plug into the turret tool holders.

I can use the same

tooling on my other turret lathe with bushings.

I just had to do a quick and dirty facing cut on the

end of some aluminum scrap to test the lathe. The old Hardinge

Chucker is now ready to earn its keep.

I can use the same

tooling on my other turret lathe with bushings.

I just had to do a quick and dirty facing cut on the

end of some aluminum scrap to test the lathe. The old Hardinge

Chucker is now ready to earn its keep.

This is the "as

cut" finish on a 3" disc of aluminum.

This is the "as

cut" finish on a 3" disc of aluminum. The above was cut with no radius on the tool. Below

is with a slight radius.

The above was cut with no radius on the tool. Below

is with a slight radius.

And after 20 seconds

with Nevr-Dull.

And after 20 seconds

with Nevr-Dull.  Once the lathe was up and earning money, I decided

to add a small steel storage box for the assorted tooling.

I picked up a used electrical box from a demolition

company to modify as the box. It had the usual pivoting cover.

Using my HF spot welder, I made the required changes

to the box.

Once the lathe was up and earning money, I decided

to add a small steel storage box for the assorted tooling.

I picked up a used electrical box from a demolition

company to modify as the box. It had the usual pivoting cover.

Using my HF spot welder, I made the required changes

to the box.

After spot welding on hinges, hasp, and staple (plus

some mods to the box), I bolted it to the end of the lathe base.

BTW - the welder worked great.

After spot welding on hinges, hasp, and staple (plus

some mods to the box), I bolted it to the end of the lathe base.

BTW - the welder worked great.

Here

it is before priming/painting.

Shelving strips were mounted inside.

Here

it is before priming/painting.

Shelving strips were mounted inside.

The shelves were

two pieces of metal bent to hook over the supports.

The turret tooling was placed inside for safe storage.

The shelves were

two pieces of metal bent to hook over the supports.

The turret tooling was placed inside for safe storage.

Here is the completed

box after painting.

Everything is lockable.

Here is the completed

box after painting.

Everything is lockable.  This is all of the "fixing" that I will do

to this old HC.

This is all of the "fixing" that I will do

to this old HC.

Here is the limited

turret tooling that came with the lathe. This is an 8 position

turret.

Here is the limited

turret tooling that came with the lathe. This is an 8 position

turret.

Disassembly has

started.

Disassembly has

started. This is the wiring setup for the

lathe. Speed control wires had been disconnected.

This is the wiring setup for the

lathe. Speed control wires had been disconnected.

Here is another

view. Notice that the belt is missing teeth!

Here is another

view. Notice that the belt is missing teeth!

Here is the speed

adjustment with the new belts. All works fine.

Here is the speed

adjustment with the new belts. All works fine.

A previous owner

added a block of nylon.

A previous owner

added a block of nylon.

This is the VFD I used.

This is the VFD I used.

It is mounted as so.

It is mounted as so.

I was able to get

the power feed working again.

I was able to get

the power feed working again.

I cleaned the coolant

pump. It works and will get remounted with the screen filter.

I cleaned the coolant

pump. It works and will get remounted with the screen filter.

This is an assortment

mounted on the turret.

This is an assortment

mounted on the turret.

These hold 1 or

2 (3/8") lathe tools.

These hold 1 or

2 (3/8") lathe tools.

This is how the

5/8" holders hook over the turret edge for accuracy.

This is how the

5/8" holders hook over the turret edge for accuracy.

This offset holder

allows machining from the side.

This offset holder

allows machining from the side.

I can use the same

tooling on my other turret lathe with bushings.

I can use the same

tooling on my other turret lathe with bushings. This is the "as

cut" finish on a 3" disc of aluminum.

This is the "as

cut" finish on a 3" disc of aluminum.

And after 20 seconds

with Nevr-Dull.

And after 20 seconds

with Nevr-Dull.

Here

it is before priming/painting.

Here

it is before priming/painting.

The shelves were

two pieces of metal bent to hook over the supports.

The shelves were

two pieces of metal bent to hook over the supports.

Here is the completed

box after painting.

Here is the completed

box after painting.