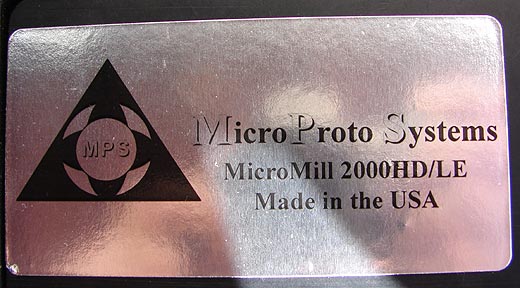

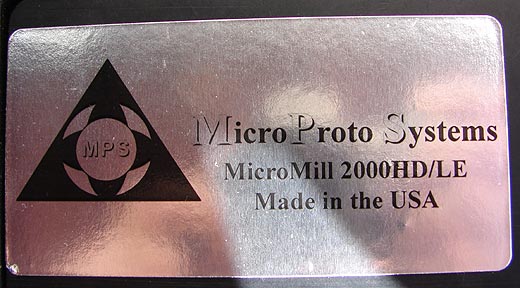

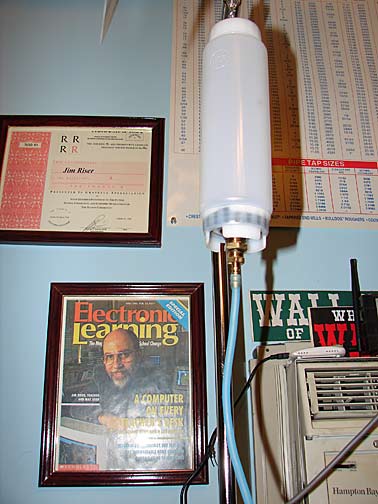

A Small MicroProto Systems MicroMill 2000 HD/LE

Copyright 2013 by James P. Riser

After coming out of a restaurant one afternoon, I noticed

that there was a pawn shop next door to it. I had not visited

a pawn shop in over 40 years - so I thought I would check it out.

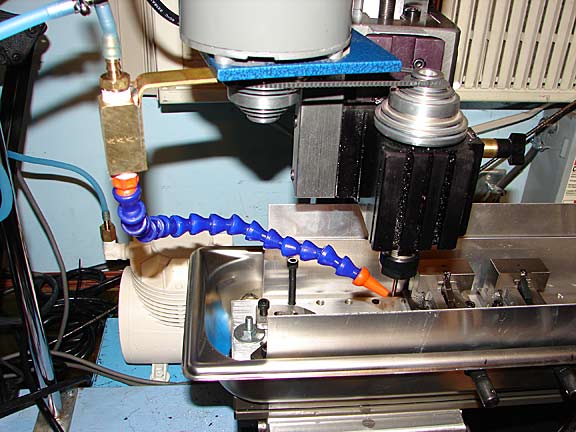

Right inside the door was this:

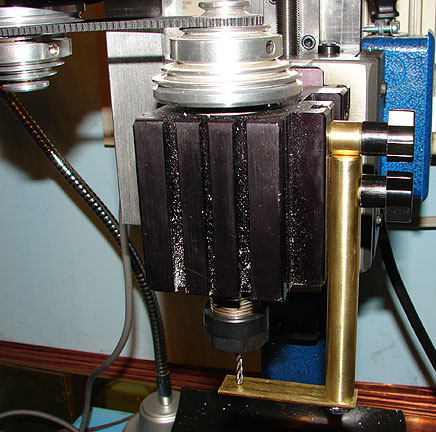

A MicroProto MicroMill

2000 HD/LE!

It was complete. The controller was in their display

case.

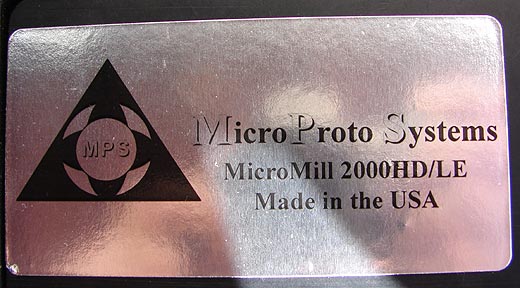

A MicroProto MicroMill

2000 HD/LE!

It was complete. The controller was in their display

case.  As one who loves business gambles, I decided to buy

it and see if I could get it running. It looked like new.

As one who loves business gambles, I decided to buy

it and see if I could get it running. It looked like new.

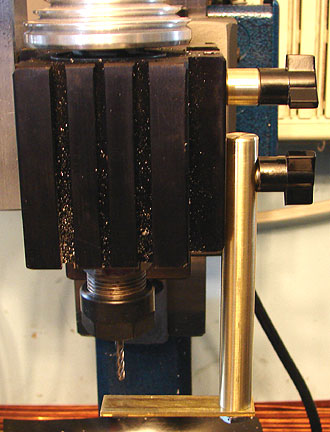

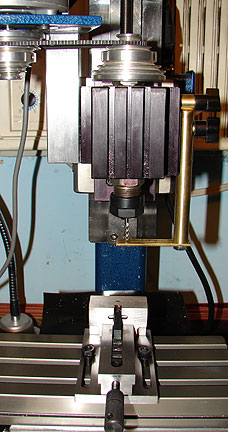

Below are several pictures of my new MicroMill. I decided

to run this machine with a module from http://www.super-tech.com/

as it converts a USB signal to the parallel interface required

by the controller and comes with an interesting software program.

Here are several views of the mill.

This little cnc machine requires a parallel connector

to run it. Newer computers do not come with parallel ports - so

a solution was required. I could go old school with an old computer

or go new school with USB. I chose to go new school.

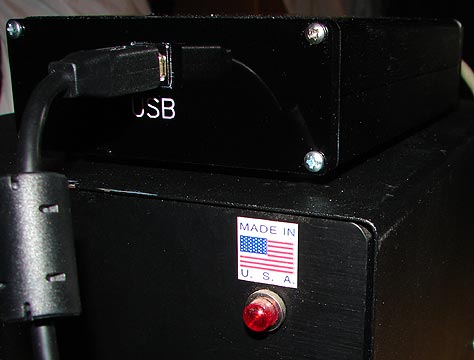

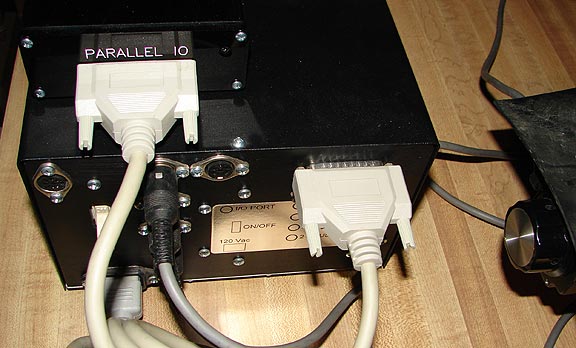

The CamPod and SuperCamXp package looked like this

when it arrived.

This little cnc machine requires a parallel connector

to run it. Newer computers do not come with parallel ports - so

a solution was required. I could go old school with an old computer

or go new school with USB. I chose to go new school.

The CamPod and SuperCamXp package looked like this

when it arrived.

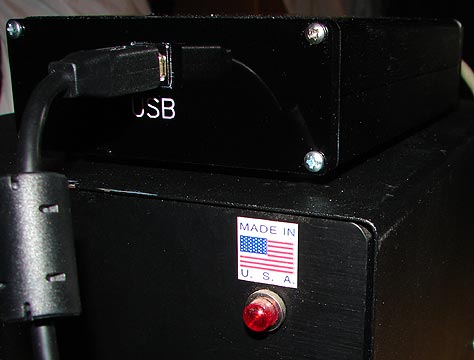

The included USB

cable plugged into the front of the CamPod unit.

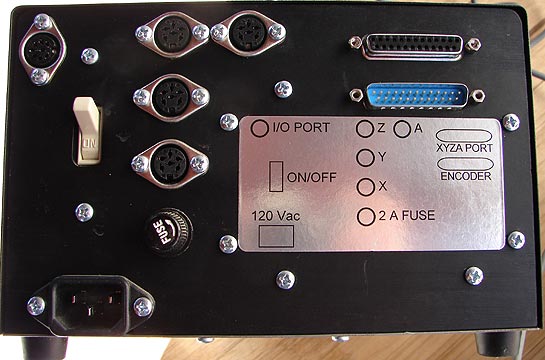

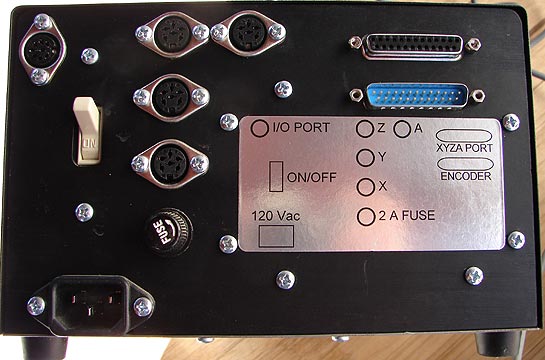

This is the back side of the controller.

The included USB

cable plugged into the front of the CamPod unit.

This is the back side of the controller.

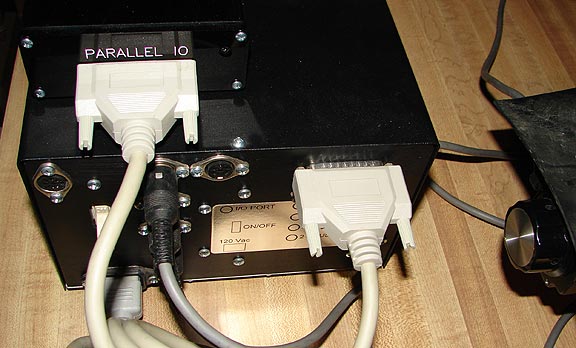

The parallel cable

attached as shown here.

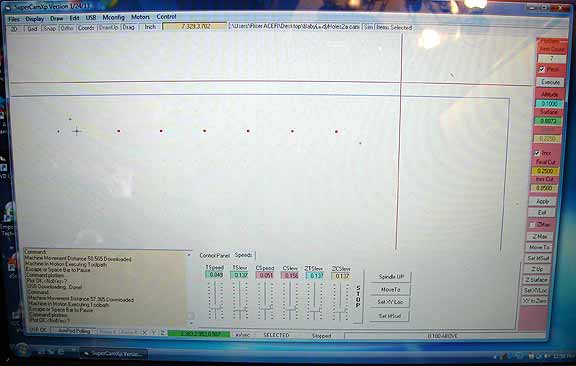

The SuperCamXp software installed smoothly on both

WindowsXP and 7. You may download a trial of the software from

this site http://www.super-tech.com/

I chose this adapter system because it will allow using

the little MicroMill with newer computers and the software should

do what I want to do easily.

The parallel cable

attached as shown here.

The SuperCamXp software installed smoothly on both

WindowsXP and 7. You may download a trial of the software from

this site http://www.super-tech.com/

I chose this adapter system because it will allow using

the little MicroMill with newer computers and the software should

do what I want to do easily.

And here are the

collets.

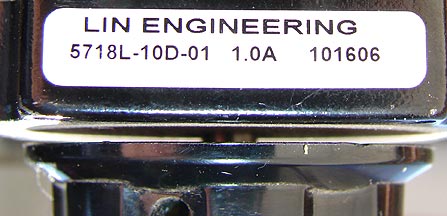

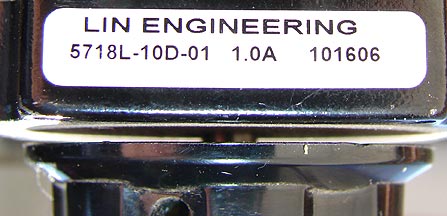

This is the label on one of the stepper motors.

And here are the

collets.

This is the label on one of the stepper motors.

This is a 1/4 hp

motor - plenty of power for my jobs.

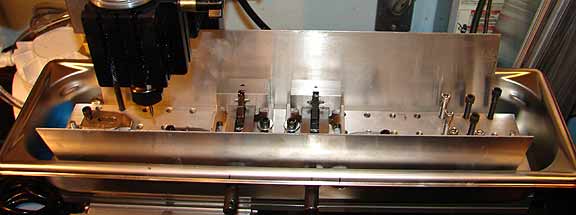

A tooling board under construction - to protect mill

table and for clamping.

This is a 1/4 hp

motor - plenty of power for my jobs.

A tooling board under construction - to protect mill

table and for clamping.

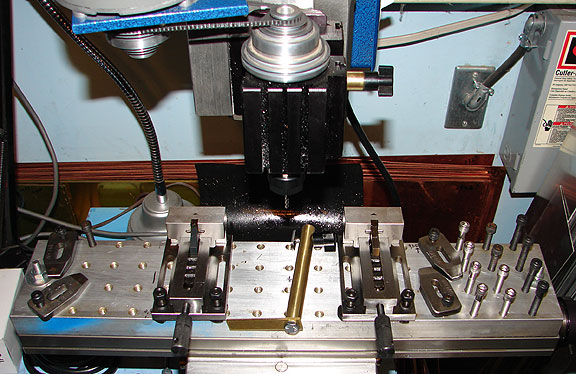

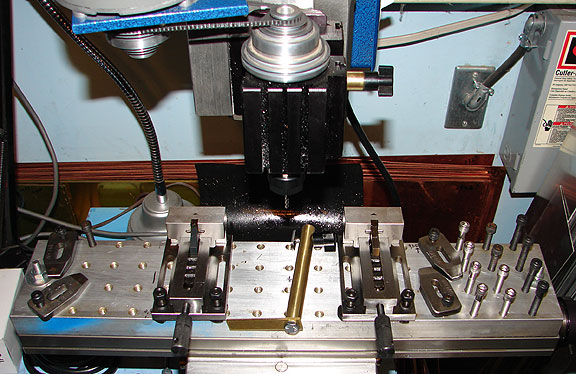

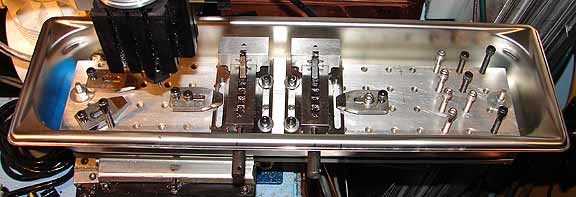

Here is the tooling

board all threaded and mounted on the mill.

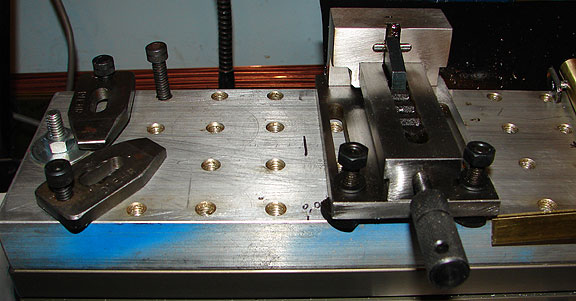

The left side with a couple hold down clamps and a

small vise.

Here is the tooling

board all threaded and mounted on the mill.

The left side with a couple hold down clamps and a

small vise.

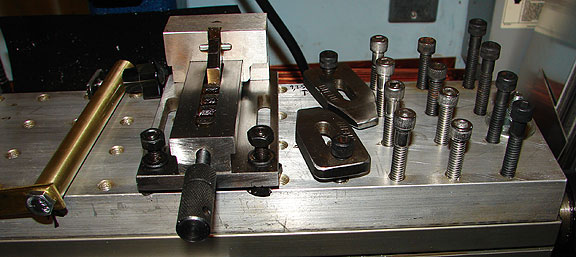

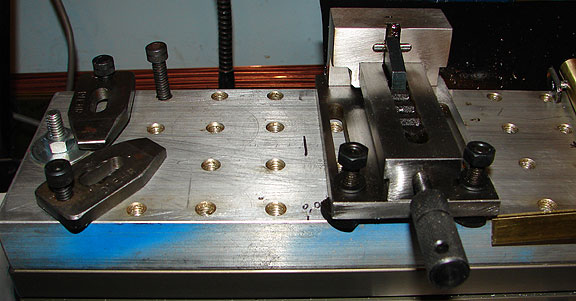

And

the right side with clamps and another small matching vise (for

longer pieces).

The assorted lengths of screws are for adjusting for

different stock thicknesses and for mounting the clamps. The brass

item is explained below.

And

the right side with clamps and another small matching vise (for

longer pieces).

The assorted lengths of screws are for adjusting for

different stock thicknesses and for mounting the clamps. The brass

item is explained below.

An Easy Method for Tool Changing on the Taig CNC Milling

Machine

Designed by James P. Riser  Tool changing on the small Taig CNC milling machine

can be time consuming and requiring another set of the "surface"

for each new tool installed. I came up with this simple solution

which allows setting tool height for one tool and quickly and

easily transferring this height to all tools as they get installed.

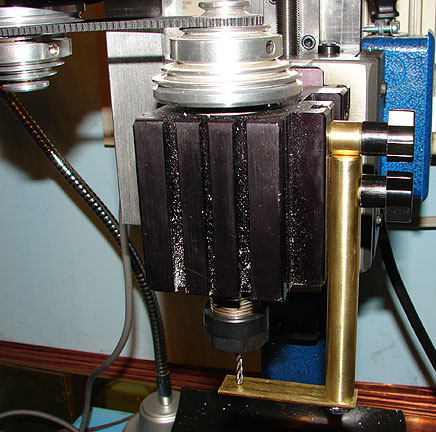

This solution is especially suited to the Taig as its

headstock has mounting slots on its body. I shall first describe

the easy construction then how to use this handy device.

Tool changing on the small Taig CNC milling machine

can be time consuming and requiring another set of the "surface"

for each new tool installed. I came up with this simple solution

which allows setting tool height for one tool and quickly and

easily transferring this height to all tools as they get installed.

This solution is especially suited to the Taig as its

headstock has mounting slots on its body. I shall first describe

the easy construction then how to use this handy device.

Construction

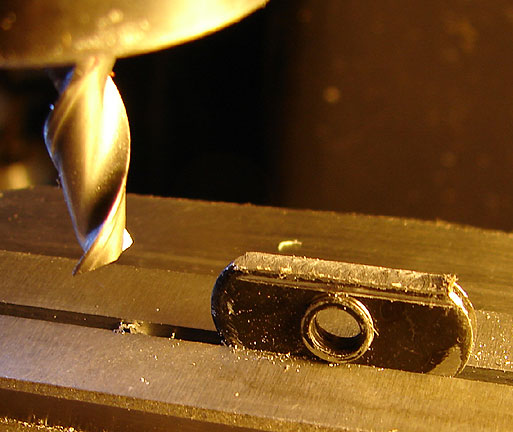

I chose brass as I wanted a soft metal for this job

- a metal that would not mess up the headstock slot. The brass

used is 1/2" diameter 360 brass. Two steel oval nuts were

milled narrower so that they would fit the slot in the side of

the headstock. After milling, the burrs were ground away.

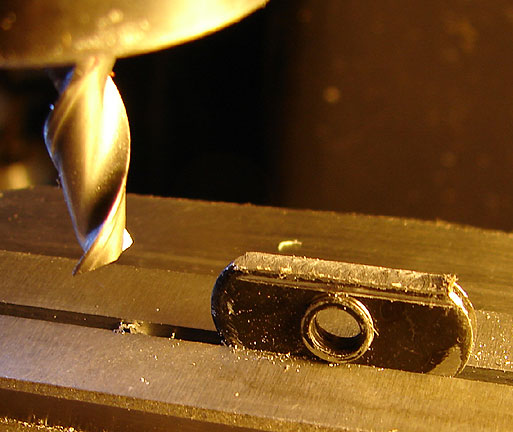

The end of the brass rod was squared off in the lathe

and center drilled then drilled.

The end of the brass rod was squared off in the lathe

and center drilled then drilled.

This end hole was threaded 1/4" - 20 tpi.

This end hole was threaded 1/4" - 20 tpi.

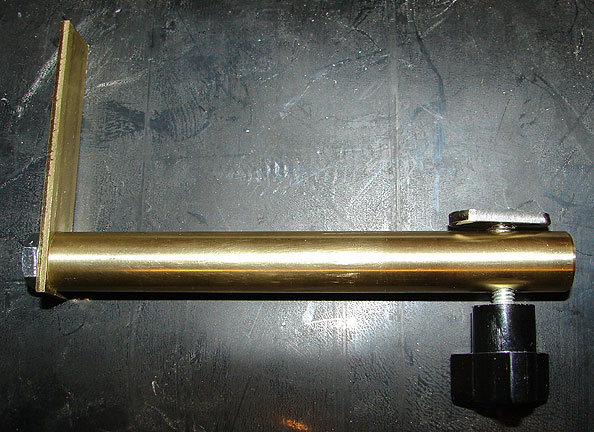

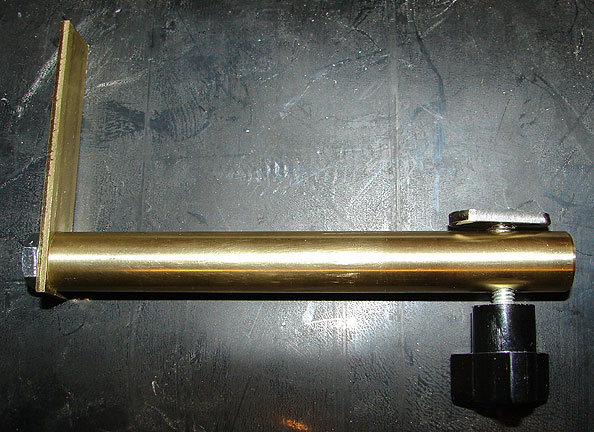

The completed tool is shown below. The brass strip

at the end is held in place by a 1/4" - 20 tpi hex head screw.

A knob head screw attaches to the oval nut.

The completed tool is shown below. The brass strip

at the end is held in place by a 1/4" - 20 tpi hex head screw.

A knob head screw attaches to the oval nut.

A 1/2" long section of brass was end drilled to

allow the screw to pass though to the second oval nut. This is

shown in place on the images below. This assembly forms an adjustable

stop for the above tool.

A 1/2" long section of brass was end drilled to

allow the screw to pass though to the second oval nut. This is

shown in place on the images below. This assembly forms an adjustable

stop for the above tool.

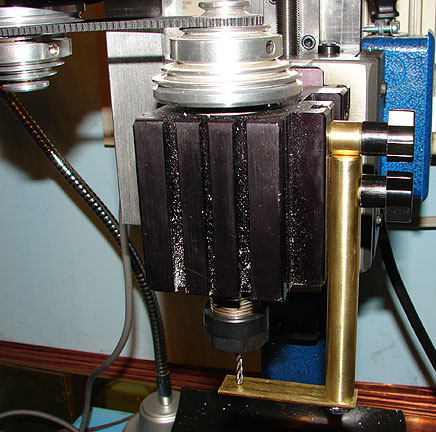

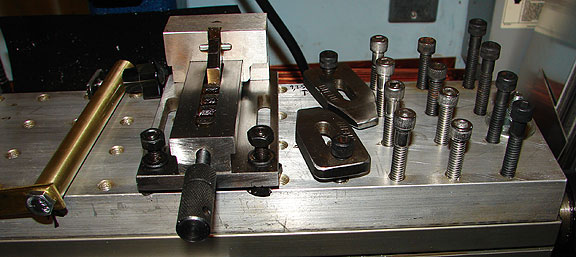

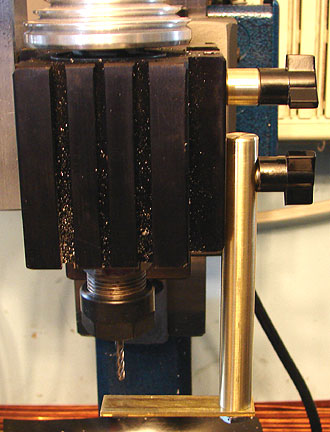

On the left is seen the brass rod of the new tool seated

into the slot. The curve of the bar's diameter allows the slot

to align the brass. It can be tightened into any desired position

with the knob.

A ball end mill is in the machine.

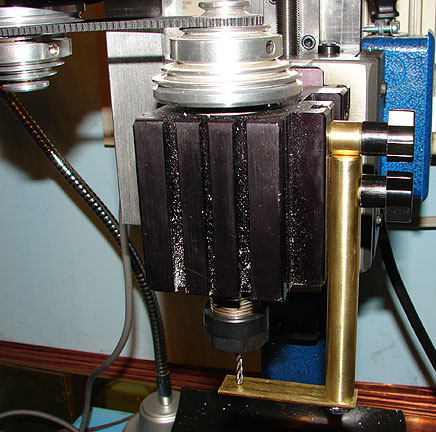

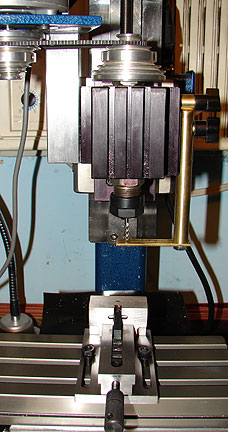

In the right image it can be seen that the brass tool

has been raised up to just kiss the end mill. It is tightened

in this position and the stop is allowed to slide down to the

top of the brass tool. The stop is then tightened with its knob.

It is now possible to remove the brass tool and set

the "surface" to run your CNC program. When it comes

to the place in the program where a tool change is called for,

the cutter being used can be dropped out, a new cutter very loosely

installed, the brass tool slid up to the stop and locked into

position. The new cutter can be allowed to merely drop down to

rest on the brass tool and be tightened into the collet. It is

now at the same position as the original tool. The brass tool

can be removed and the CNC program resumed. This will work even

if a different size of collet needs to be installed along with

the new cutter.

Nothing could be simpler, cheaper, nor faster.

On the left is seen the brass rod of the new tool seated

into the slot. The curve of the bar's diameter allows the slot

to align the brass. It can be tightened into any desired position

with the knob.

A ball end mill is in the machine.

In the right image it can be seen that the brass tool

has been raised up to just kiss the end mill. It is tightened

in this position and the stop is allowed to slide down to the

top of the brass tool. The stop is then tightened with its knob.

It is now possible to remove the brass tool and set

the "surface" to run your CNC program. When it comes

to the place in the program where a tool change is called for,

the cutter being used can be dropped out, a new cutter very loosely

installed, the brass tool slid up to the stop and locked into

position. The new cutter can be allowed to merely drop down to

rest on the brass tool and be tightened into the collet. It is

now at the same position as the original tool. The brass tool

can be removed and the CNC program resumed. This will work even

if a different size of collet needs to be installed along with

the new cutter.

Nothing could be simpler, cheaper, nor faster.

Here is a close-up view of the stop and the brass tool

in the raised position.

Here is a close-up view of the stop and the brass tool

in the raised position.

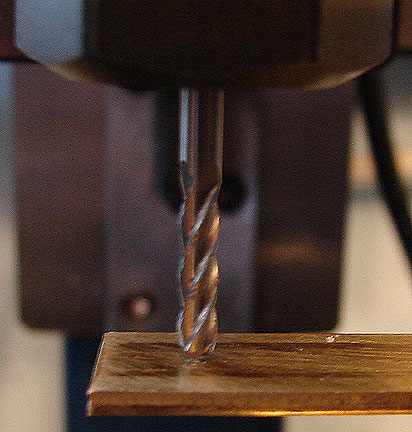

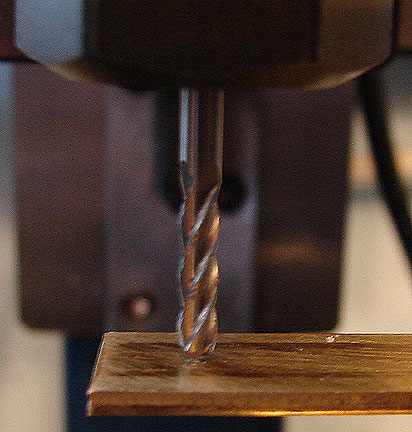

Here is a cutter just kissing the brass plate.

Here is a cutter just kissing the brass plate.

The final item is shown below.

The final item is shown below.

The relay switch

box for controlling the spindle/collant/vacuum by software.

Things have come together nicely and I am ready to

cut material.

The relay switch

box for controlling the spindle/collant/vacuum by software.

Things have come together nicely and I am ready to

cut material.

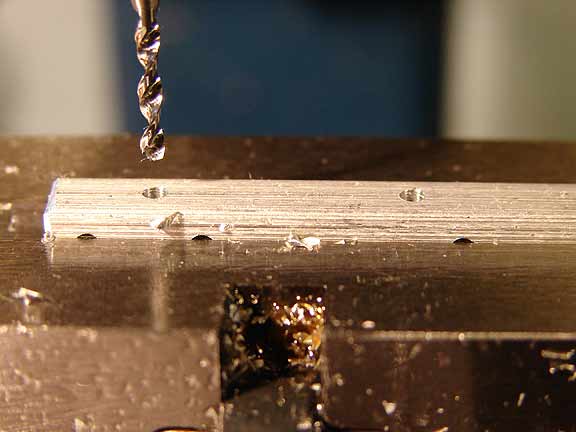

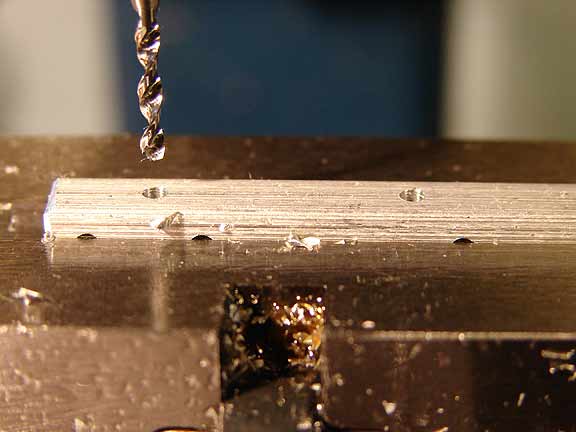

OK, first job with this little gem was one in which

I needed to drill thousands of small holes in very specific locations

on lengths of square aluminum bar.

I drilled with

cutting oil and things were a mess - chips and oil all over the

machine.

Here is a close-up of part of the job.

I drilled with

cutting oil and things were a mess - chips and oil all over the

machine.

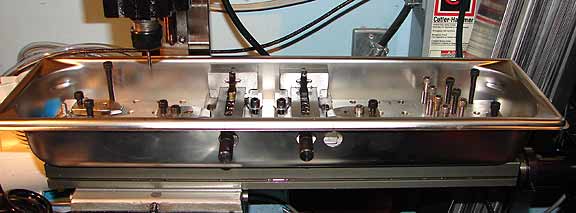

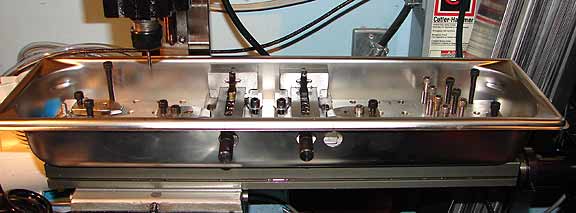

Here is a close-up of part of the job.  I decided to add a chip pan for collecting chips and

oil. This would keep things better contained.

I decided to add a chip pan for collecting chips and

oil. This would keep things better contained.

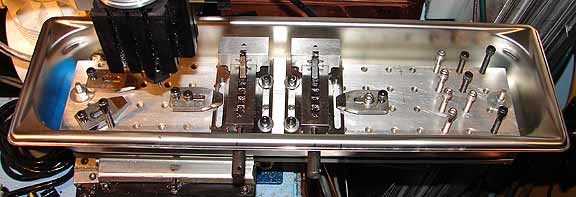

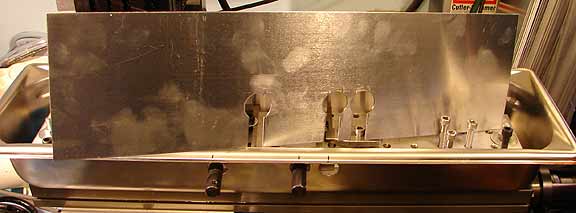

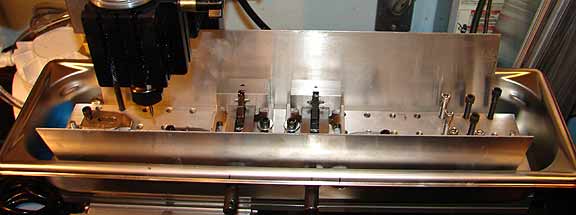

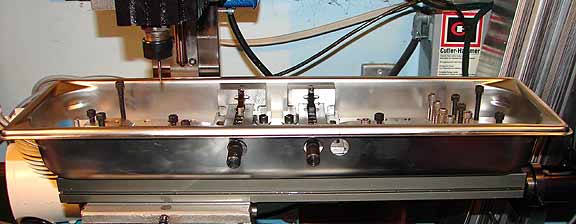

Notice that I have drilled handle

holes for the double vise setup.

Barely visible in the back left pan corner is the drain

petcock.

Notice that I have drilled handle

holes for the double vise setup.

Barely visible in the back left pan corner is the drain

petcock.

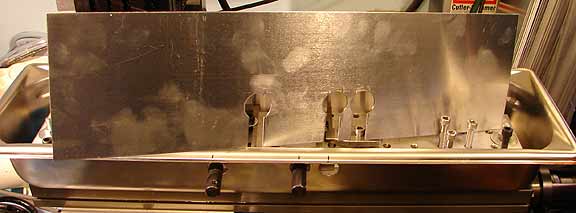

The third hole in front allows

me to move the right vise 1" to the right.

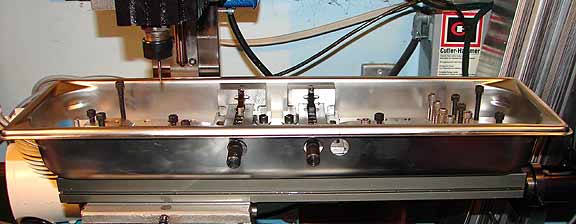

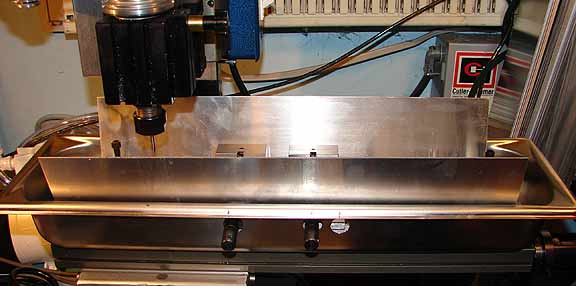

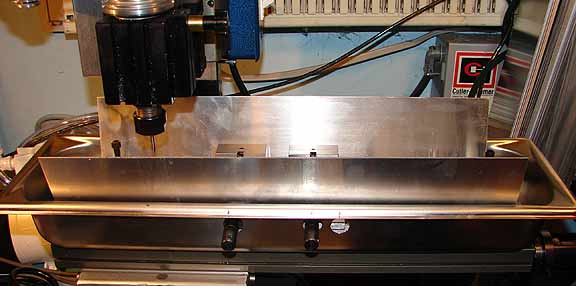

To better contain chips and splash, I added a removable

aluminum plate.

The third hole in front allows

me to move the right vise 1" to the right.

To better contain chips and splash, I added a removable

aluminum plate.

The removable front

plate looks like this.

Additional views with the two shields in place:

The removable front

plate looks like this.

Additional views with the two shields in place:

I also have a shorter rear shield for working close

to the tooling board.

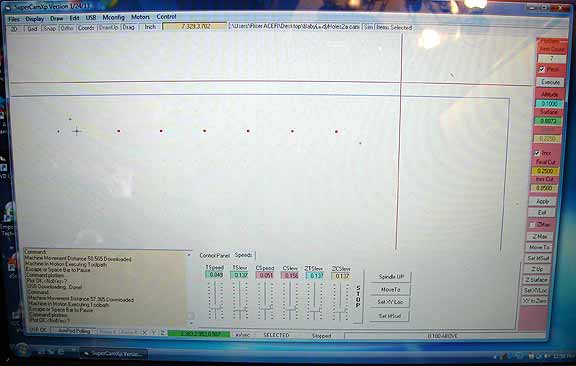

Using the slick SuperCamXp software required only a

series of points for drilling the holes.

I also have a shorter rear shield for working close

to the tooling board.

Using the slick SuperCamXp software required only a

series of points for drilling the holes.

The holes were

all peck drilled in .050" increments.

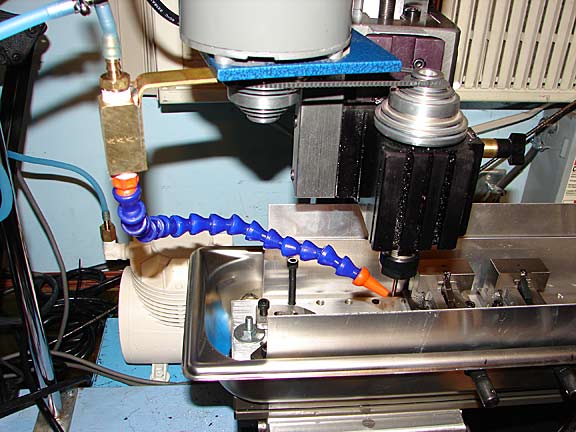

OK, my drip system is completed.

The holes were

all peck drilled in .050" increments.

OK, my drip system is completed.

I have set it up

so that I may blow air only or ...

Cutting oil/lubricant.

I have set it up

so that I may blow air only or ...

Cutting oil/lubricant.  The small air compressor is used to blow chips away

when cutting dry. The plastic bottle will contain the cutting

oil.

The small air compressor is used to blow chips away

when cutting dry. The plastic bottle will contain the cutting

oil.

The two small valves

control both air and oil flows.

Control of the air or oil flow to the cutting tip.

The two small valves

control both air and oil flows.

Control of the air or oil flow to the cutting tip.

This new system eliminates the need to dab on cutting

oil or to brush away dry chips.

This new system eliminates the need to dab on cutting

oil or to brush away dry chips.

A MicroProto MicroMill

2000 HD/LE!

A MicroProto MicroMill

2000 HD/LE!

The included USB

cable plugged into the front of the CamPod unit.

The included USB

cable plugged into the front of the CamPod unit.

The parallel cable

attached as shown here.

The parallel cable

attached as shown here. And here are the

collets.

And here are the

collets.

This is a 1/4 hp

motor - plenty of power for my jobs.

This is a 1/4 hp

motor - plenty of power for my jobs.

Here is the tooling

board all threaded and mounted on the mill.

Here is the tooling

board all threaded and mounted on the mill.

And

the right side with clamps and another small matching vise (for

longer pieces).

And

the right side with clamps and another small matching vise (for

longer pieces).

The relay switch

box for controlling the spindle/collant/vacuum by software.

The relay switch

box for controlling the spindle/collant/vacuum by software. I drilled with

cutting oil and things were a mess - chips and oil all over the

machine.

I drilled with

cutting oil and things were a mess - chips and oil all over the

machine.

Notice that I have drilled handle

holes for the double vise setup.

Notice that I have drilled handle

holes for the double vise setup.

The third hole in front allows

me to move the right vise 1" to the right.

The third hole in front allows

me to move the right vise 1" to the right.

The removable front

plate looks like this.

The removable front

plate looks like this.

The holes were

all peck drilled in .050" increments.

The holes were

all peck drilled in .050" increments. I have set it up

so that I may blow air only or ...

I have set it up

so that I may blow air only or ...

The two small valves

control both air and oil flows.

The two small valves

control both air and oil flows.