Testing of the Sears Powder Coating Gun

Variable Speed Self Contained Blower Model

Copyright 2005 by James

P. Riser

This page will describe some testing I did with the

new Sears Craftsman Powder Coating System.

The system includes the gun, one color cup, transformer,

high temperature masking tape, high temperature plugs, hooks,

and a plastic case.

The Sears powder coating material is supplied in small

bags.  The powder in each bag should cover up to 7 square

feet of surface.

The powder in each bag should cover up to 7 square

feet of surface.

I

have purchased a variety of powders for testing from Columbia

Coatings

I

have purchased a variety of powders for testing from Columbia

Coatings

I wanted a powder coating system that I could run without

turning on my noisy air compressor. So I thought I would try the

new Sears Powder Coating System. It was on sale - so I decided

to act now!

Since I only manufacture rather small items, I require

only a smaller size of oven for curing the powder on many items.

Fortunately I discovered a toaster oven at Walmart for less than

$13! This was about what I wanted to spend on such an oven. In

addition to small size, I wanted a window in the door so that

I could monitor the curing process. This little oven even has

a timer on it to shut down the elements after up to 15 minutes.

If I like everything, I'll pick up a larger oven for quantity

production.

This is the $13

toaster oven I selected for my use.

Here is the oven "on" during the curing process.

This is the $13

toaster oven I selected for my use.

Here is the oven "on" during the curing process.

The sample to be powder coated is a small spun copper

dish (similar to the products I will want to powder coat).

Here is a close up view of curing in operation - the

powder has begun to flow.

The copper was sanded down to bare metal and cleaned

off with lacquer thinner. The coating I selected is a textured

coating with black and gold flecks.

I did not clean the scrap steel plate used to support

the dish; but it also ended up with a nice coating.

The sample to be powder coated is a small spun copper

dish (similar to the products I will want to powder coat).

Here is a close up view of curing in operation - the

powder has begun to flow.

The copper was sanded down to bare metal and cleaned

off with lacquer thinner. The coating I selected is a textured

coating with black and gold flecks.

I did not clean the scrap steel plate used to support

the dish; but it also ended up with a nice coating.

Here is another

view. There are three layers of coating on this test sample.

I applied the three layers in this manner: 1st layer

as usual; 2nd layer as soon as the powder began to flow; 3rd layer

when the second layer began to flow.

This will give you an idea of the size involved.

Here is another

view. There are three layers of coating on this test sample.

I applied the three layers in this manner: 1st layer

as usual; 2nd layer as soon as the powder began to flow; 3rd layer

when the second layer began to flow.

This will give you an idea of the size involved.  I am very pleased with the new Sears equipment. The

finished coating is very professional looking. This system will

definitely meet my needs.

I am very pleased with the new Sears equipment. The

finished coating is very professional looking. This system will

definitely meet my needs.

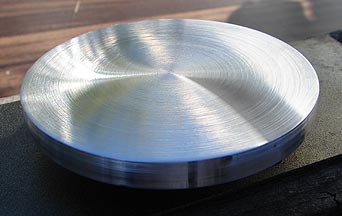

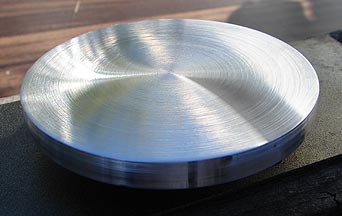

Here is additional testing on a 3" diameter aluminum

disc about 1/4" thick.

I machined the

surface and smoothed with a 150 grit abrasive pad using oil.

The rim of the disc was lightly filed then sanded.

I wanted a surface for the powder to adhere to and I wanted to

determine if the machining would still be visible.

This disc was supported by a smaller disc to raise

it up off of the support steel plate.

I machined the

surface and smoothed with a 150 grit abrasive pad using oil.

The rim of the disc was lightly filed then sanded.

I wanted a surface for the powder to adhere to and I wanted to

determine if the machining would still be visible.

This disc was supported by a smaller disc to raise

it up off of the support steel plate.

The ground wire

was clamped to the supporting steel plate.

The ground wire

was clamped to the supporting steel plate.

The gun power was

attached - to charge the powder as it passes the tip electrode.

The gun power was

attached - to charge the powder as it passes the tip electrode.

The powder after

being applied by the gun.

The powder after

being applied by the gun.  The powder is only held on to the metal by static electricity.

The powder is only held on to the metal by static electricity.

Things look like this as the disc is placed into the

preheated oven.

Notice that the powder looks like fine grit.

Things look like this as the disc is placed into the

preheated oven.

Notice that the powder looks like fine grit.

Once the disc comes

up to temperature, the powder begins to flow.

The flow continues with the surface becoming smoother.

Once the disc comes

up to temperature, the powder begins to flow.

The flow continues with the surface becoming smoother.

When the metal

was at temperature and the flow smoothed out, I set the timer

for 15 minutes.

This is how things looked when the powder was fully

cured.

When the metal

was at temperature and the flow smoothed out, I set the timer

for 15 minutes.

This is how things looked when the powder was fully

cured.

Here is a comparison between the two tested objects.

The three step layer on the thin copper dish is much finer grained.

The coating on the thicker aluminum disc is much more

textured and the gold veining more pronounced.

Both are professional looking and feeling coatings.

Here is a comparison between the two tested objects.

The three step layer on the thin copper dish is much finer grained.

The coating on the thicker aluminum disc is much more

textured and the gold veining more pronounced.

Both are professional looking and feeling coatings.

A Test of Transparent blue Powder

One of the colors that I want to use is a transparent

blue.

This is how it comes from Columbia Coatings

I have added an

oven thermometer to my setup.

This aluminum cylinder is to be powder coated for this

test.

I have added an

oven thermometer to my setup.

This aluminum cylinder is to be powder coated for this

test. Notice the blemishes on the top. I wanted to

determine how "sloppy" I could be and still get a good

coating.

Notice the blemishes on the top. I wanted to

determine how "sloppy" I could be and still get a good

coating.

After cleaning

the cylinder with lacquer thinner, I set it in the oven to preheat.

Columbia Coatings indicates that this powder should

be used over their chrome base coat; but I wanted to see how it

would look over semi polished aluminum without the chrome base

coat.

The transparent blue powder was poured into the color

cup.

After cleaning

the cylinder with lacquer thinner, I set it in the oven to preheat.

Columbia Coatings indicates that this powder should

be used over their chrome base coat; but I wanted to see how it

would look over semi polished aluminum without the chrome base

coat.

The transparent blue powder was poured into the color

cup.  The applied powder looked like this...

The applied powder looked like this...

There is always

a little blowby of powder onto the gun.

This stray powder can be quickly removed with a good

blow or with a damp towel.

The still warm cylinder was returned to the oven.

There is always

a little blowby of powder onto the gun.

This stray powder can be quickly removed with a good

blow or with a damp towel.

The still warm cylinder was returned to the oven.

After a few minutes

at between 375 and 400 degrees, the powder begins to flow.

When fully cured (around 20-25 minutes), the cylinder

looks like this.

After a few minutes

at between 375 and 400 degrees, the powder begins to flow.

When fully cured (around 20-25 minutes), the cylinder

looks like this.  The coating is beautiful - except for where I made

a few mistakes. I coated outdoors and just when I began to spray

the powder, the wind kicked up. A few specs of dust found their

way onto the cylinder top as the powder was sprayed. You can also

see traces in the coating from lint (from the paper towel I used

to clean the cylinder - lint free cloth towel from now on). Also

the original blemishes left on the semi polished cylinder for

testing do show through. A higher degree of buffing would have

taken care of this problem. Defects can be seen in the image below.

This is the surface with the problems.

The coating is beautiful - except for where I made

a few mistakes. I coated outdoors and just when I began to spray

the powder, the wind kicked up. A few specs of dust found their

way onto the cylinder top as the powder was sprayed. You can also

see traces in the coating from lint (from the paper towel I used

to clean the cylinder - lint free cloth towel from now on). Also

the original blemishes left on the semi polished cylinder for

testing do show through. A higher degree of buffing would have

taken care of this problem. Defects can be seen in the image below.

This is the surface with the problems.

I also was interested in seeing if I could buff up

the aluminum right next to the powder coating without ruining

the coating. This can not be done with a painted item.

I also was interested in seeing if I could buff up

the aluminum right next to the powder coating without ruining

the coating. This can not be done with a painted item.

Here is the same

cylinder after I polished the rim on my buffer.

And a close-up of the line between the newly polished

top and the coating. Smooth!

Here is the same

cylinder after I polished the rim on my buffer.

And a close-up of the line between the newly polished

top and the coating. Smooth!  I also wanted to test the coating for flexibility -

so I bent the plate that was supporting the cylinder.

I also wanted to test the coating for flexibility -

so I bent the plate that was supporting the cylinder. Conclusions:

1. The Sears syatem works.

2. This system works with powders from other suppliers.

3. Surface prep is critical - especially for transparent

coatings.

4. Do not try to powder coat in the dusty wind.

5. The coatings are tough yet flexible.

6. With a well buffed finish the Columbia Coatings

transparent powders should work well - even without the chrome

base coat.

In conclusion, I feel that the new Sears syatem can

provide the home shop worker with a viable powder coating method.

New addition!!!

Since I am running a small business, I wanted to do

powder coating on several of the items that I manufacture. The

small toaster oven was fine for testing and a few one-of-a-kind

items; but too small for production purposes. So when I received

a 20% off coupon from Harbor freight, I decided to finally get

one of their powder coating ovens (made in India). I considered

converting an old kitchen oven into a powder coating oven; but

wanted to stick with 110 voltage as I would be moving things around

in the shop and 220 might not be where it was needed for an oven.

In addition, this looks better.

Conclusions:

1. The Sears syatem works.

2. This system works with powders from other suppliers.

3. Surface prep is critical - especially for transparent

coatings.

4. Do not try to powder coat in the dusty wind.

5. The coatings are tough yet flexible.

6. With a well buffed finish the Columbia Coatings

transparent powders should work well - even without the chrome

base coat.

In conclusion, I feel that the new Sears syatem can

provide the home shop worker with a viable powder coating method.

New addition!!!

Since I am running a small business, I wanted to do

powder coating on several of the items that I manufacture. The

small toaster oven was fine for testing and a few one-of-a-kind

items; but too small for production purposes. So when I received

a 20% off coupon from Harbor freight, I decided to finally get

one of their powder coating ovens (made in India). I considered

converting an old kitchen oven into a powder coating oven; but

wanted to stick with 110 voltage as I would be moving things around

in the shop and 220 might not be where it was needed for an oven.

In addition, this looks better.

This is what the

oven looks like.

Here are the controls.

This is what the

oven looks like.

Here are the controls.

The

interior circulating fan was a feature that I felt I wanted.

The interior is all stainless steel and comes with

one rack and two hanging bars - fine for my needs.

The

interior circulating fan was a feature that I felt I wanted.

The interior is all stainless steel and comes with

one rack and two hanging bars - fine for my needs.

The three heating

elements are in the bottom of the oven.

Another feaure I wanted was the built in mercury thermometer.

The three heating

elements are in the bottom of the oven.

Another feaure I wanted was the built in mercury thermometer.

This larger oven will make my work much easier. If

interested, you may find the oven specs on the Harbor freight

site.

This larger oven will make my work much easier. If

interested, you may find the oven specs on the Harbor freight

site.

I

have purchased a variety of powders for testing from Columbia

Coatings

I

have purchased a variety of powders for testing from Columbia

Coatings This is the $13

toaster oven I selected for my use.

This is the $13

toaster oven I selected for my use.

Here is another

view. There are three layers of coating on this test sample.

Here is another

view. There are three layers of coating on this test sample.

I machined the

surface and smoothed with a 150 grit abrasive pad using oil.

I machined the

surface and smoothed with a 150 grit abrasive pad using oil.

The ground wire

was clamped to the supporting steel plate.

The ground wire

was clamped to the supporting steel plate. The gun power was

attached - to charge the powder as it passes the tip electrode.

The gun power was

attached - to charge the powder as it passes the tip electrode.

The powder after

being applied by the gun.

The powder after

being applied by the gun.

Once the disc comes

up to temperature, the powder begins to flow.

Once the disc comes

up to temperature, the powder begins to flow.

When the metal

was at temperature and the flow smoothed out, I set the timer

for 15 minutes.

When the metal

was at temperature and the flow smoothed out, I set the timer

for 15 minutes.

I have added an

oven thermometer to my setup.

I have added an

oven thermometer to my setup.

After cleaning

the cylinder with lacquer thinner, I set it in the oven to preheat.

After cleaning

the cylinder with lacquer thinner, I set it in the oven to preheat.

There is always

a little blowby of powder onto the gun.

There is always

a little blowby of powder onto the gun.

After a few minutes

at between 375 and 400 degrees, the powder begins to flow.

After a few minutes

at between 375 and 400 degrees, the powder begins to flow.

Here is the same

cylinder after I polished the rim on my buffer.

Here is the same

cylinder after I polished the rim on my buffer.

This is what the

oven looks like.

This is what the

oven looks like.

The

interior circulating fan was a feature that I felt I wanted.

The

interior circulating fan was a feature that I felt I wanted.

The three heating

elements are in the bottom of the oven.

The three heating

elements are in the bottom of the oven.