Modifications to a Thornton Windlass

Copyright 2012 by James

P. Riser

To make a Thornton Windlass more versatile, the following

modifications were done.

An oddity of the Thornton Windlass has always been

how it was to be attached to things using a small square of cloth

and safety pins. The goal with this project was to make a Thornton

Windlass a more useable tool for a working pro.

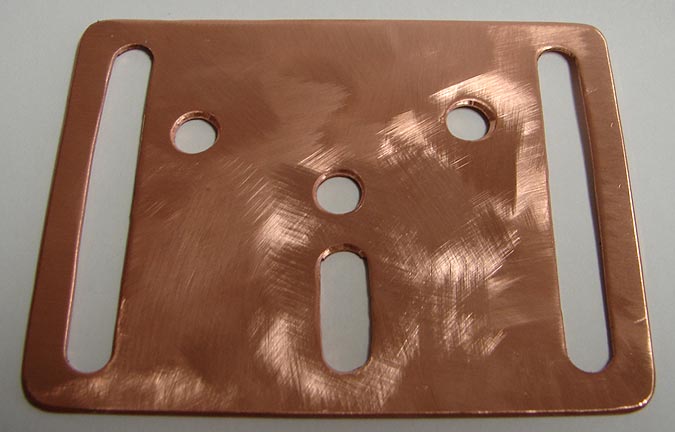

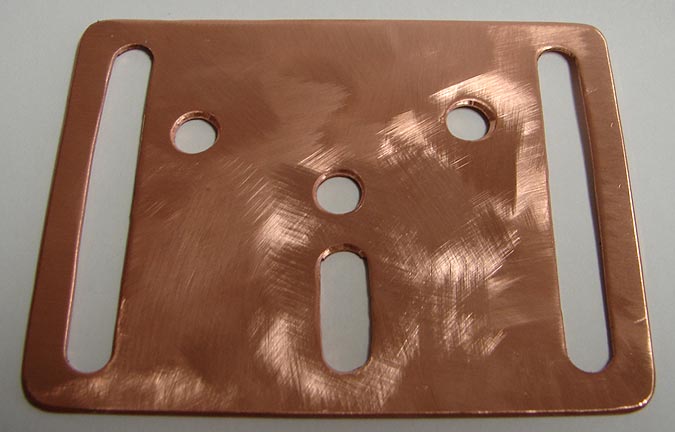

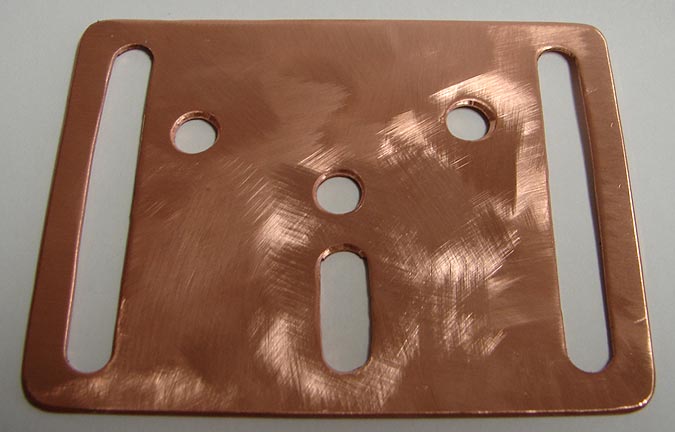

A copper backing

plate was fabricated.

As was done on my Thornton Windlass once owned by Al

DeLage, a small spring was soldered onto the reel body to cushion

the stopping of the reel. This spring is mounted at a tangent

to the internal drum to prevent thread wear. This spring will

help avoid thread breakage and internal reel damage. Letting the

thread free fly back into the reel can break the reel - especially

the newer

versions.

A copper backing

plate was fabricated.

As was done on my Thornton Windlass once owned by Al

DeLage, a small spring was soldered onto the reel body to cushion

the stopping of the reel. This spring is mounted at a tangent

to the internal drum to prevent thread wear. This spring will

help avoid thread breakage and internal reel damage. Letting the

thread free fly back into the reel can break the reel - especially

the newer

versions.

Notice the three connecting loops. I wanted to mount

the Thornton to this back plate without damaging the original

reel in case an "undo" might be desired in the future.

This is how the plate fits the back of the Thornton

Windlass.

Notice the three connecting loops. I wanted to mount

the Thornton to this back plate without damaging the original

reel in case an "undo" might be desired in the future.

This is how the plate fits the back of the Thornton

Windlass.

The belt loops

were bent to allow clearance.

Here is the plate in the final position.

The belt loops

were bent to allow clearance.

Here is the plate in the final position.

Wire was threaded

through the reel loops.

The completed wire threading looked like this.

Wire was threaded

through the reel loops.

The completed wire threading looked like this.

The wire was covered

with leather.

The completed modifications will allow the Thornton

Windlass to be worn on a belt on either the right or left side

of the performer's body.

The front view.

The wire was covered

with leather.

The completed modifications will allow the Thornton

Windlass to be worn on a belt on either the right or left side

of the performer's body.

The front view.

The back view.

The back view.

A copper backing

plate was fabricated.

A copper backing

plate was fabricated. A copper backing

plate was fabricated.

A copper backing

plate was fabricated.

The belt loops

were bent to allow clearance.

The belt loops

were bent to allow clearance.

Wire was threaded

through the reel loops.

Wire was threaded

through the reel loops.

The wire was covered

with leather.

The wire was covered

with leather.

The back view.

The back view.