The Lastest Addition to My Shop

Copyright 2008 by James

P. Riser

A Burke #4 Milling Machine

This Burke #4 is the perfect size for the items that

I manufacture. I am the second machine user on this milling machine

and it all appears to be in very good condition.

Here is the Burke disassembled for the 500 mile trip

home. It is shown here in the back of my mini van.  We placed it in the van using a forklift at the dealer's

place and I removed it using my engine hoist.

We placed it in the van using a forklift at the dealer's

place and I removed it using my engine hoist.

The images below were all made while the machine is

in my carport for assembly and cleaning.

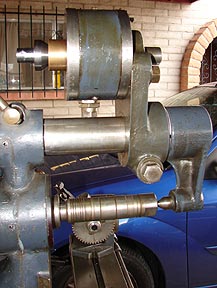

Assembled it looks

like this.

Assembled it looks

like this.

The castings indicate

the point of origin.

The castings indicate

the point of origin.  The serial number indicates a manufactured date of

September, 1946.

The serial number indicates a manufactured date of

September, 1946.

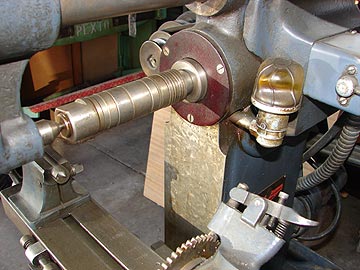

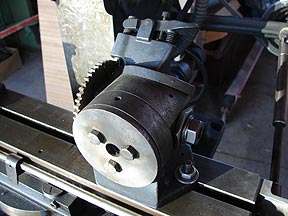

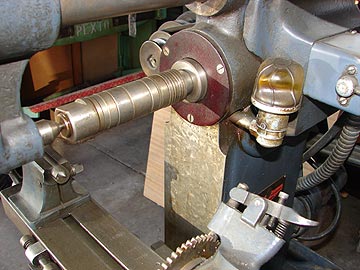

The business end

of the machine is shown here without any cutter on the 1"

arbor.

These 7/8" and 1"arbors, collet drawbar for

3SB collets, and milling holder came with the machine.

The business end

of the machine is shown here without any cutter on the 1"

arbor.

These 7/8" and 1"arbors, collet drawbar for

3SB collets, and milling holder came with the machine.

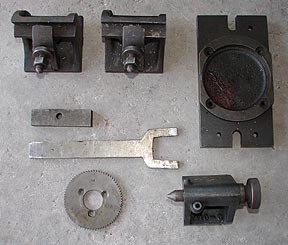

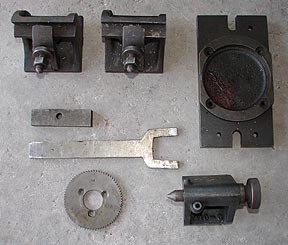

In addition, I

received a 72 notch index plate, bar clamps, vise base, and extra

center.

The original vise was not found; but I will use a vintage

quick clamp Palmgren vise with this machine.

In addition, I

received a 72 notch index plate, bar clamps, vise base, and extra

center.

The original vise was not found; but I will use a vintage

quick clamp Palmgren vise with this machine.

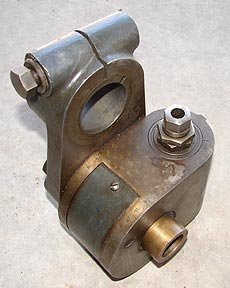

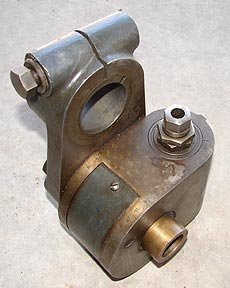

Also included was the Vertical milling head.  I need to machine an arbor for this attachment - an

easy, quick job.

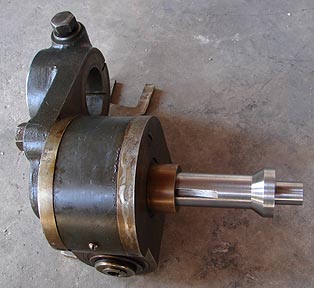

The new steel arbor for the vertical head is done!

I need to machine an arbor for this attachment - an

easy, quick job.

The new steel arbor for the vertical head is done!

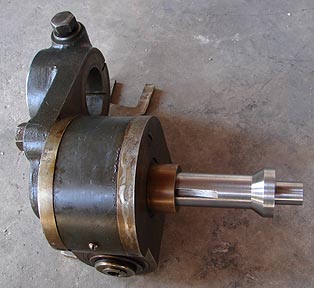

I machined the right end of the new shaft for the vertical

milling head to

fit into a 3/4" #9 B&S collet rather than

machining the taper on to the shaft.

This arrangement should work fine.

The other end of the shaft is center drilled and threaded.

I have received a few emails asking why I machined

a short stub on this shaft rather than the B&S #9 taper. I

did so for convenience. The short stub for connecting with a 3/4"

collet allows me to leave the vertical head on the overarm and

merely pull it out a little bit then swing it up out of the way

for when using the horizontal milling arbors. This way I seldon

need to totally remove the vertical head from the overarm shaft

and it is conviently there when needed for a quick job. This is

a more time efficient setup than with the very long taper sticking

out in the way. The images below illustrate this.

I machined the right end of the new shaft for the vertical

milling head to

fit into a 3/4" #9 B&S collet rather than

machining the taper on to the shaft.

This arrangement should work fine.

The other end of the shaft is center drilled and threaded.

I have received a few emails asking why I machined

a short stub on this shaft rather than the B&S #9 taper. I

did so for convenience. The short stub for connecting with a 3/4"

collet allows me to leave the vertical head on the overarm and

merely pull it out a little bit then swing it up out of the way

for when using the horizontal milling arbors. This way I seldon

need to totally remove the vertical head from the overarm shaft

and it is conviently there when needed for a quick job. This is

a more time efficient setup than with the very long taper sticking

out in the way. The images below illustrate this.

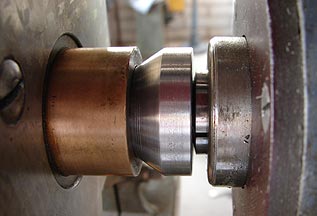

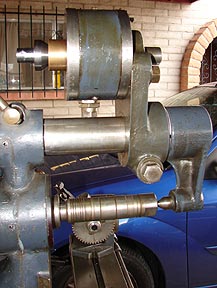

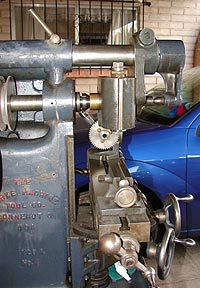

Up and out of the

way on the left and down for use on the right...

Up and out of the

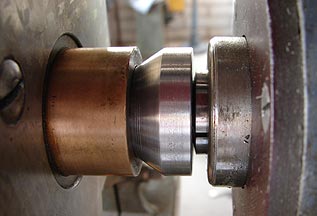

way on the left and down for use on the right...  Here is the actual connection between the 3/4"

collet and the arbor end.

Here is the actual connection between the 3/4"

collet and the arbor end.

The collet draw

bar shown above, the indexing head, and the vertical head use

3SB/3C collets.

The 3SB collets and 3C collets are the same size -

so no problem there.

For any vertical milling that this machine can not

do, I'll use my Rusnok milling machine.

The collet draw

bar shown above, the indexing head, and the vertical head use

3SB/3C collets.

The 3SB collets and 3C collets are the same size -

so no problem there.

For any vertical milling that this machine can not

do, I'll use my Rusnok milling machine.

The

swivel indexing head is the older style without the name.

The

swivel indexing head is the older style without the name.

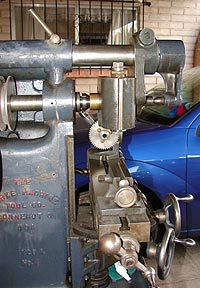

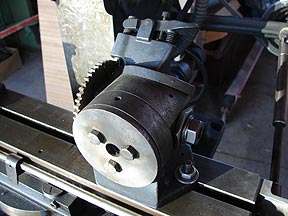

This is the power

feed drive system.

This is the power

feed drive system.  I'll tune the drive shaft in a few days.

The power feed is controlled by this lever.

I'll tune the drive shaft in a few days.

The power feed is controlled by this lever.

This lever arm

shuts off the power feed when the cut has been made.

Yes, there is one small "oops" on the milling

table. It will affect nothing I will be doing.

Notice that this machine has the Universal Table and

most of the "frosting" is still there.

This lever arm

shuts off the power feed when the cut has been made.

Yes, there is one small "oops" on the milling

table. It will affect nothing I will be doing.

Notice that this machine has the Universal Table and

most of the "frosting" is still there.

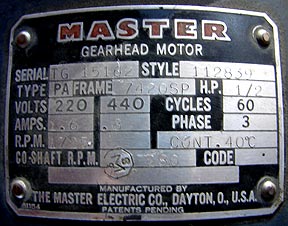

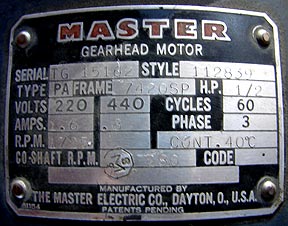

The motor is the

Master Gearhead.

The motor is the

Master Gearhead.  In checking the gear oil in the motor, I discovered

that it was low (as shown on the dip stick).

In checking the gear oil in the motor, I discovered

that it was low (as shown on the dip stick).

After topping it

off, the dip stick indicates full (filled only to the top mark

on stick).

After topping it

off, the dip stick indicates full (filled only to the top mark

on stick).

This is the switch

and lubes for the spindle head.

I'll be replacing the lubes with classic style brass/glass

drip lubricators. I have already replaced the wiring.

I just finished welding up a rolling base so that I

can move the machine into the shop.

This is the switch

and lubes for the spindle head.

I'll be replacing the lubes with classic style brass/glass

drip lubricators. I have already replaced the wiring.

I just finished welding up a rolling base so that I

can move the machine into the shop.  I have many of my machines mounted on such bases for

easy moving within the shop.

This Burke #4 should be an excellent addition to my

machines and I look forward to getting it cleaned up ready to

work.

Click here to go to installation

of the VFD onto this machine.

I have many of my machines mounted on such bases for

easy moving within the shop.

This Burke #4 should be an excellent addition to my

machines and I look forward to getting it cleaned up ready to

work.

Click here to go to installation

of the VFD onto this machine.

Assembled it looks

like this.

Assembled it looks

like this.

The castings indicate

the point of origin.

The castings indicate

the point of origin.

The business end

of the machine is shown here without any cutter on the 1"

arbor.

The business end

of the machine is shown here without any cutter on the 1"

arbor.

In addition, I

received a 72 notch index plate, bar clamps, vise base, and extra

center.

In addition, I

received a 72 notch index plate, bar clamps, vise base, and extra

center.

Up and out of the

way on the left and down for use on the right...

Up and out of the

way on the left and down for use on the right...

The collet draw

bar shown above, the indexing head, and the vertical head use

3SB/3C collets.

The collet draw

bar shown above, the indexing head, and the vertical head use

3SB/3C collets. The

swivel indexing head is the older style without the name.

The

swivel indexing head is the older style without the name.

This is the power

feed drive system.

This is the power

feed drive system.

This lever arm

shuts off the power feed when the cut has been made.

This lever arm

shuts off the power feed when the cut has been made.

The motor is the

Master Gearhead.

The motor is the

Master Gearhead.

After topping it

off, the dip stick indicates full (filled only to the top mark

on stick).

After topping it

off, the dip stick indicates full (filled only to the top mark

on stick). This is the switch

and lubes for the spindle head.

This is the switch

and lubes for the spindle head.