A1 - The Ratchet Wheel

Copyright 2011 by James P. Riser

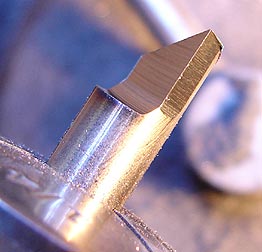

The ratchet wheel begins with the grinding of a new

fly cutter. The projection left from cutting off the previous

fly cutter is first ground away. The hss drill blank is then ground

just slightly past halfway for clearance purposes. The grinding

is again done on my Gortom 265 bench top grinder.

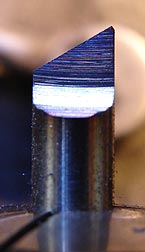

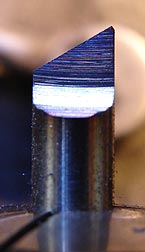

The angle is next set to 60 degrees.

The angle is next set to 60 degrees.

The angle on the end is ground then clearance on all

sides of the cutter. Clearance is critical.

The angle on the end is ground then clearance on all

sides of the cutter. Clearance is critical.

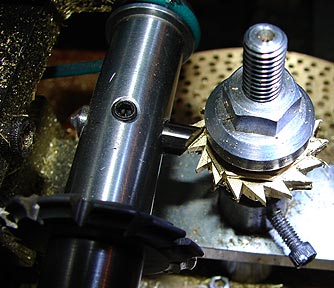

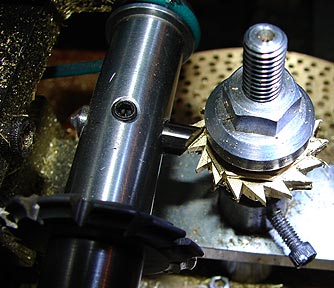

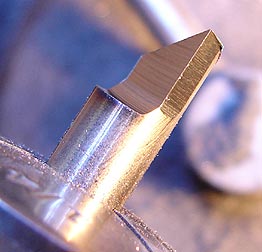

After clearances have been ground, the cutter now looks

like this and is ready to be ground off of the end of the hss

drill blank rod. The new fly cutter gets mounted in the wheel

engine cutter arbor.

After clearances have been ground, the cutter now looks

like this and is ready to be ground off of the end of the hss

drill blank rod. The new fly cutter gets mounted in the wheel

engine cutter arbor.

The brass ratchet wheel blanks are punched out.

The brass ratchet wheel blanks are punched out.  An emergency collet is modified to securely hold the

brass blank for hole drilling and sizing.

An emergency collet is modified to securely hold the

brass blank for hole drilling and sizing.

After final sizing, the blanks are ready to be cut.

After final sizing, the blanks are ready to be cut.

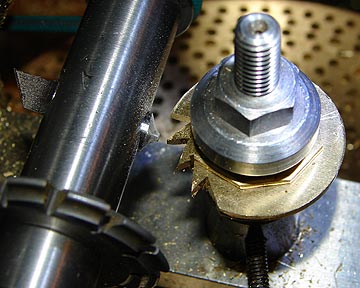

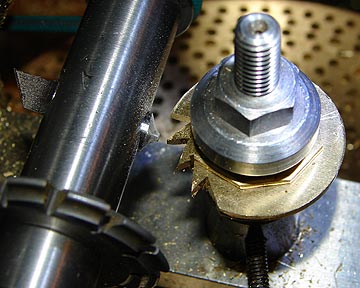

They are cut on

my Chronos Wheel Engine.

They are cut on

my Chronos Wheel Engine.  A completed ratchet wheel looks like this.

A completed ratchet wheel looks like this.  More to come as I get time.

Click here to go to page 5

More to come as I get time.

Click here to go to page 5

They are cut on

my Chronos Wheel Engine.

They are cut on

my Chronos Wheel Engine.