A1 - the Air Brake or Governor

.GIF)

Copyright 2011 by James P. Riser

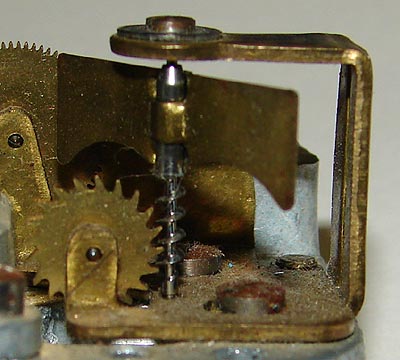

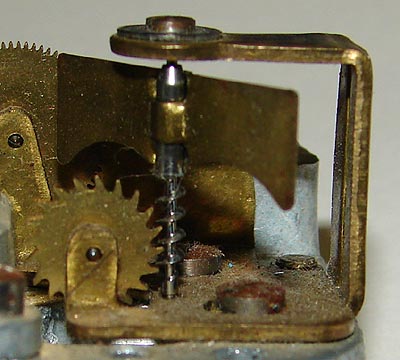

A nicely functioning air brake is critical to this

project. The air brake or governor controls the speed of the entire

unit by rapidly spinning a small fan. The drag caused by the air

against the fan blades is what serves as a silent brake for the

mechanism. Without this governor, the entire mechanism would rapidly

unwind with no means of control. Such air brakes are most often

seen as part of a music box movement.

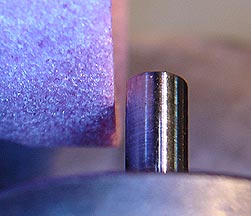

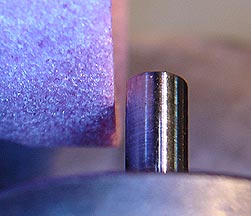

Here is an air brake on an old music box.  The brake wheels just made are what will drive the

special worm gear of the fan. Below you may see the wheels that

I just made. And above you may see a similar wheel driving worm

of the fan.

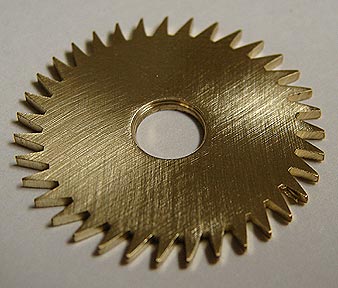

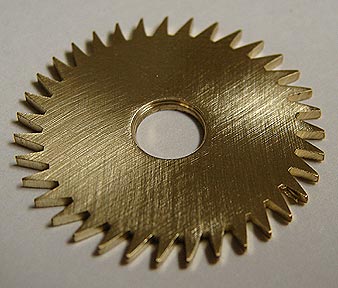

The brake wheels just made are what will drive the

special worm gear of the fan. Below you may see the wheels that

I just made. And above you may see a similar wheel driving worm

of the fan.

I decided to make my fan arbor with its worm gear from

stainless steel. This should provide decades of service with no

rusting of the mechanism. With very careful reworking, a stainless

steel lag screw could be adapted to my needs. The head was first

removed and the arbor end trued in my Sheldon lathe. Everything

is held in collets for accuracy.

I decided to make my fan arbor with its worm gear from

stainless steel. This should provide decades of service with no

rusting of the mechanism. With very careful reworking, a stainless

steel lag screw could be adapted to my needs. The head was first

removed and the arbor end trued in my Sheldon lathe. Everything

is held in collets for accuracy.

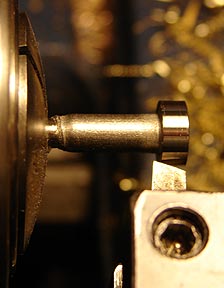

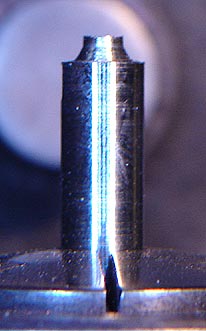

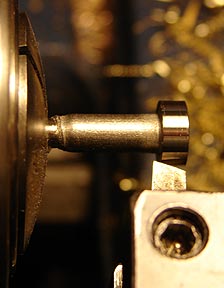

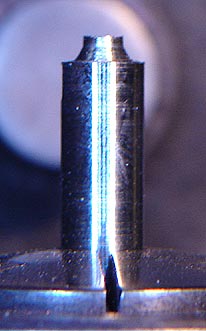

This is the screw

end after machining.

The next step was to do some precision grinding on

both ends of the fan arbor.

The benchtop Gorton 265 grinder was again put to work

for this. The angle was set to "0".

This is the screw

end after machining.

The next step was to do some precision grinding on

both ends of the fan arbor.

The benchtop Gorton 265 grinder was again put to work

for this. The angle was set to "0".

The wheel was dressed as required.

The wheel was dressed as required.

The arbor was chucked

up for grinding.

The arbor was chucked

up for grinding.

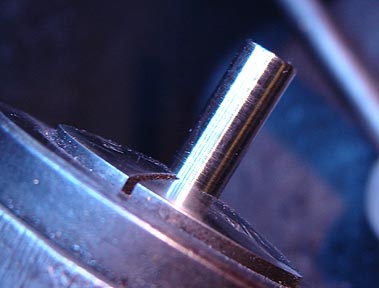

The end was ground

to form a small projection.

The projection was sized to just fit into the center

of this tiny shielded ball bearing assembly.

The end was ground

to form a small projection.

The projection was sized to just fit into the center

of this tiny shielded ball bearing assembly.

Here is this bearing

mounted onto the just ground end of the fan arbor.

Here is this bearing

mounted onto the just ground end of the fan arbor.

The other end of

this arbor has a matching projection ground on it.

The other end of

this arbor has a matching projection ground on it.  Here is what the arbor now looked like when I mounted

it on the Sheldon lathe to true up the threads.

Here is what the arbor now looked like when I mounted

it on the Sheldon lathe to true up the threads.

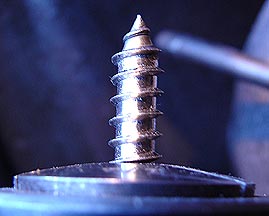

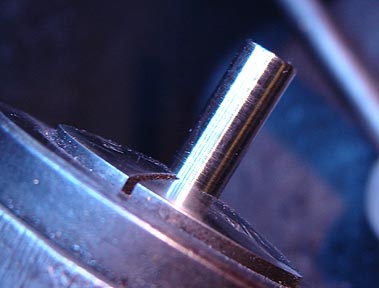

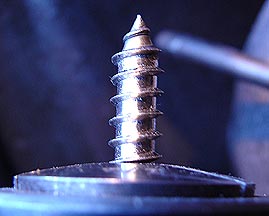

Notice that I ground a couple flats at the fan end

of this arbor. These will come in handy when mounting the fan

later. Notice in the pictures below that I have cleaned up the

threads and polished the thread surfaces so that the brake drive

wheel will not hang up on any rough spots. These threads are now

extremely smooth. The air brake will not work if the threads are

left rough and unpolished.

Notice that I ground a couple flats at the fan end

of this arbor. These will come in handy when mounting the fan

later. Notice in the pictures below that I have cleaned up the

threads and polished the thread surfaces so that the brake drive

wheel will not hang up on any rough spots. These threads are now

extremely smooth. The air brake will not work if the threads are

left rough and unpolished.

Here is a closeup

view of the ends.

Here is a closeup

view of the ends.

Here are the bearings

and how they mount on the arbor.

Here are the bearings

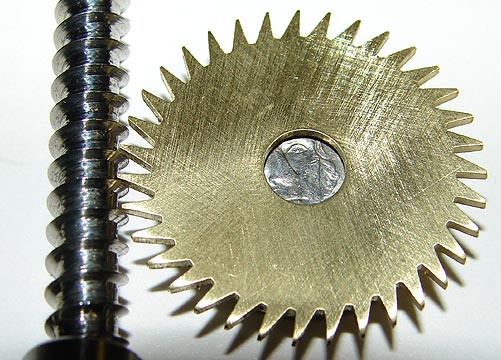

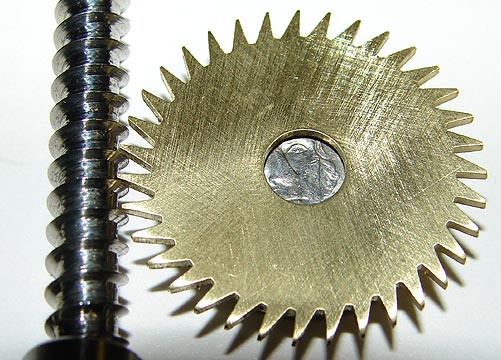

and how they mount on the arbor.  Also shown above and below is how the brake drive wheel

meshes with the threads on the worm of the arbor. Everything was

calculated and machined so that three teeth of the drive wheel

engage the worm at the same time. This spreads out energy so that

there is minimal friction in the system.

Also shown above and below is how the brake drive wheel

meshes with the threads on the worm of the arbor. Everything was

calculated and machined so that three teeth of the drive wheel

engage the worm at the same time. This spreads out energy so that

there is minimal friction in the system.

The brass fan (to

be made later) will mount on the top end of the arbor.

Click here to go to page 4

Click here to go to page 6

The brass fan (to

be made later) will mount on the top end of the arbor.

Click here to go to page 4

Click here to go to page 6

This is the screw

end after machining.

This is the screw

end after machining.

The arbor was chucked

up for grinding.

The arbor was chucked

up for grinding.

The end was ground

to form a small projection.

The end was ground

to form a small projection.

Here is this bearing

mounted onto the just ground end of the fan arbor.

Here is this bearing

mounted onto the just ground end of the fan arbor. The other end of

this arbor has a matching projection ground on it.

The other end of

this arbor has a matching projection ground on it.

Here is a closeup

view of the ends.

Here is a closeup

view of the ends.

Here are the bearings

and how they mount on the arbor.

Here are the bearings

and how they mount on the arbor.

The brass fan (to

be made later) will mount on the top end of the arbor.

The brass fan (to

be made later) will mount on the top end of the arbor.