A1 - Making the Barrel

Copyright 2011 by James P. Riser

On this page I shall document how I am making the barrel

for five items. Some of the methods of construction will differ

from standard clock construction. The items that I am making will

not be running 24 hours a day for hundreds of years so I am deviating

from standard designs which are necessary for clocks. These items

are not clocks and will only be run for seconds at a time perhaps

only a few times per year. Those familiar with clock building,

will see where I veer from the norm.

The first deviation from the norm ... I make the barrel

hooks or anchors from steel nail heads. I have found the steel

perfect for this purpose.

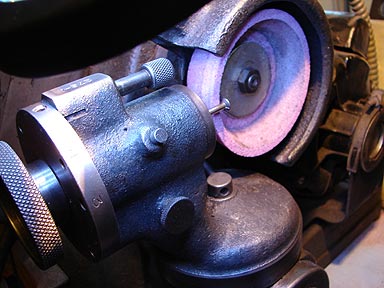

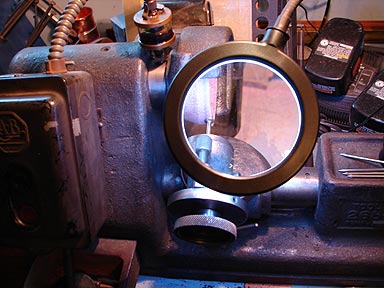

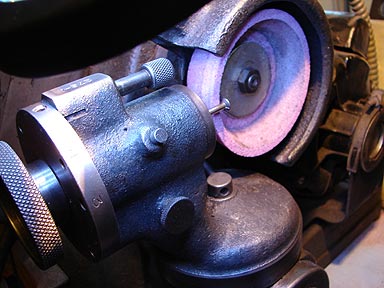

I am using my Gorton

265 bench top tool grinder for this task.

The angle is set to "0" degrees.

I am using my Gorton

265 bench top tool grinder for this task.

The angle is set to "0" degrees.

The nail is mounted

in the correct size of collet and grinding begins.

The nail is mounted

in the correct size of collet and grinding begins.

The shank is ground

true.

The shank is ground

true.

And two sides ground

down.

And two sides ground

down.  Cleaned up the barrel hooks to be look like this.

Cleaned up the barrel hooks to be look like this.  These hooks will be cut off from the nail body shortly.

The second deviation from the norm is that these hooks will work

no matter which direction the spring is wound. This makes design

changes down the road much easier if I choose to reverse the direction

of motion.

These hooks will be cut off from the nail body shortly.

The second deviation from the norm is that these hooks will work

no matter which direction the spring is wound. This makes design

changes down the road much easier if I choose to reverse the direction

of motion.

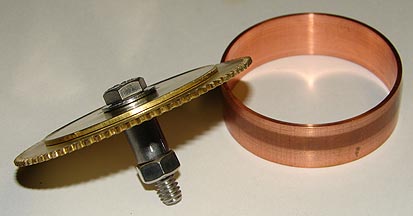

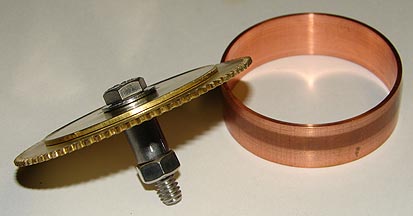

To keep the works visually appealing

and interesting, I will be

using heavy copper for the barrel bodies.

This is a rough idea of how things will look after

a bit more work.

To keep the works visually appealing

and interesting, I will be

using heavy copper for the barrel bodies.

This is a rough idea of how things will look after

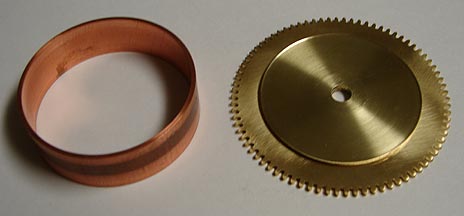

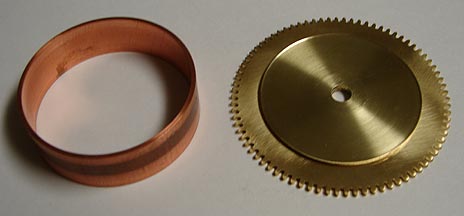

a bit more work.  2" discs of brass were punched out as part of

the barrel assembly.

2" discs of brass were punched out as part of

the barrel assembly.

These are the parts

made up until now.

The brass disc just fits into the copper ring.

These are the parts

made up until now.

The brass disc just fits into the copper ring.

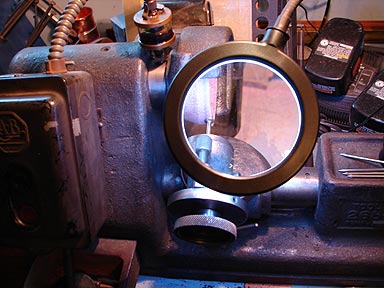

After center drilling

with a hole to match the gear hole, the disc will go here.

All parts will be aligned and soldered in this position

to make the barrel body.

After center drilling

with a hole to match the gear hole, the disc will go here.

All parts will be aligned and soldered in this position

to make the barrel body.  In order to get the disc ready for soldering a pot

chuck must be modified to securely hold the disc.

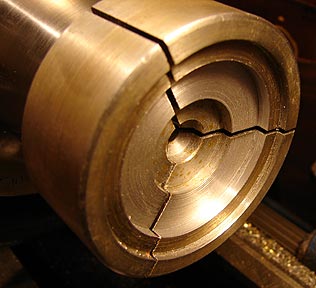

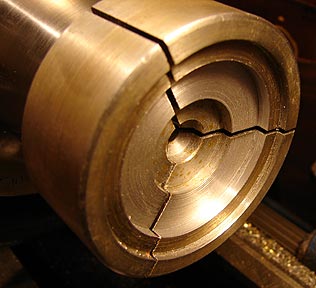

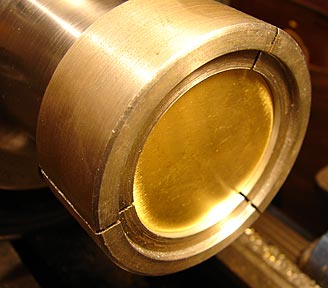

In order to get the disc ready for soldering a pot

chuck must be modified to securely hold the disc.

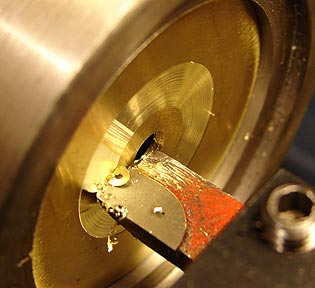

The center hole is be carefully drilled.

The center hole is be carefully drilled.

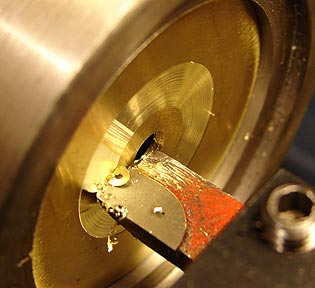

The disc hole is carefully drilled to final size.

The disc hole is carefully drilled to final size.  The resulting hole is just fine for my needs with no

measurable loss of concentricity.

The disc is then machined to leave the center high

and a slight edge rim.

The resulting hole is just fine for my needs with no

measurable loss of concentricity.

The disc is then machined to leave the center high

and a slight edge rim.

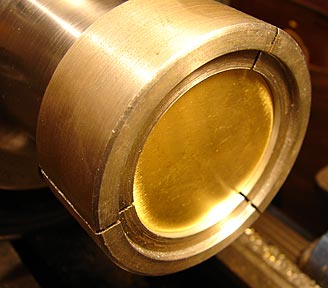

This raised center

will help to reduce friction when in operation.

The parts now look like this. The slight edge rim provides

increased surface area for soldering.

This raised center

will help to reduce friction when in operation.

The parts now look like this. The slight edge rim provides

increased surface area for soldering.

The disc hole lines up with the barrel wheel hole.

This disc just fits inside the barrel body.

The disc hole lines up with the barrel wheel hole.

This disc just fits inside the barrel body.

Assembled, the parts look like this.

Assembled, the parts look like this.

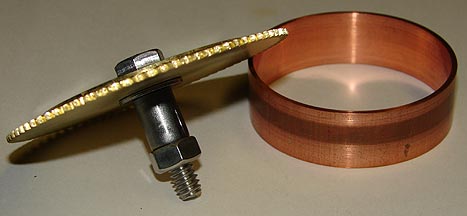

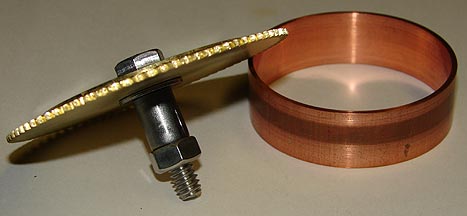

A stainless steel

bolt, two washers, a steel spacer, and a nut will hold the parts

for soldering.

This is how the parts are secured for soldering.

A stainless steel

bolt, two washers, a steel spacer, and a nut will hold the parts

for soldering.

This is how the parts are secured for soldering.

Once the disc and barrel wheel are bolted together,

the barrel body is fitted over the disc. This is a test fit of

the parts.

Once the disc and barrel wheel are bolted together,

the barrel body is fitted over the disc. This is a test fit of

the parts.

The next step with the barrel will the installation

of the barrel anchor or hook. This will be followed by soldering

everything together.

Before I finish the barrels, I am going to start on

what I call the brake wheel. That info is on page 4.

Click here to go to page 2

Click here to go to page 4

The next step with the barrel will the installation

of the barrel anchor or hook. This will be followed by soldering

everything together.

Before I finish the barrels, I am going to start on

what I call the brake wheel. That info is on page 4.

Click here to go to page 2

Click here to go to page 4

I am using my Gorton

265 bench top tool grinder for this task.

I am using my Gorton

265 bench top tool grinder for this task.

The nail is mounted

in the correct size of collet and grinding begins.

The nail is mounted

in the correct size of collet and grinding begins. The shank is ground

true.

The shank is ground

true.

And two sides ground

down.

And two sides ground

down.

These are the parts

made up until now.

These are the parts

made up until now.

After center drilling

with a hole to match the gear hole, the disc will go here.

After center drilling

with a hole to match the gear hole, the disc will go here.

This raised center

will help to reduce friction when in operation.

This raised center

will help to reduce friction when in operation.

A stainless steel

bolt, two washers, a steel spacer, and a nut will hold the parts

for soldering.

A stainless steel

bolt, two washers, a steel spacer, and a nut will hold the parts

for soldering.