A1 - the Brake Wheel

Copyright 2011 by James P. Riser

In order to cut the brake wheels I need to grind a

special fly cutter to use on my Chronos Wheel Engine. The grinder

is again my bench top Gorton 265 grinder.

I make my fly cutters

out of 1/4" diameter HSS drill blanks.

The HSS rod looks like this.

I make my fly cutters

out of 1/4" diameter HSS drill blanks.

The HSS rod looks like this.  The rod is mounted in the 1/4" collet on the grinder

and the angle set to 0 degrees. For this special cutter I will

grind a little past half way through the tip of the rod. Since

this is HSS, a little discoloring from grinding heat will hurt

nothing.

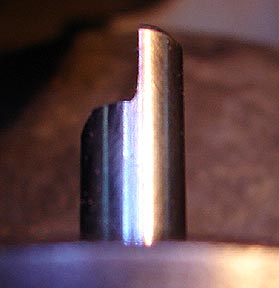

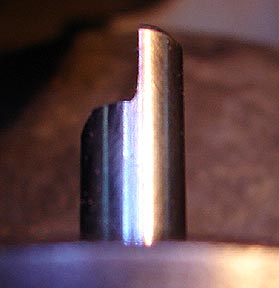

The rod is mounted in the 1/4" collet on the grinder

and the angle set to 0 degrees. For this special cutter I will

grind a little past half way through the tip of the rod. Since

this is HSS, a little discoloring from grinding heat will hurt

nothing.

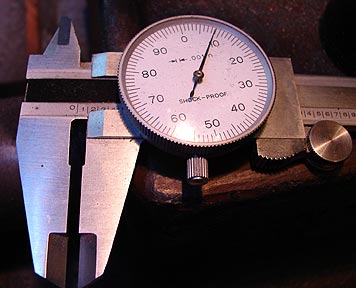

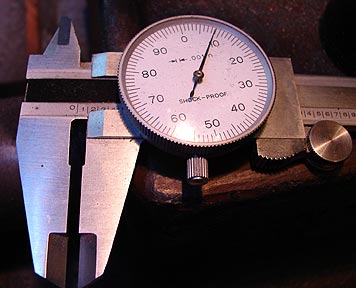

Once I have ground a little past half way, I measure

things with a dial caliper. The reason I grind slightly past half

way is to make certain that the cutter will have the clearances

necessary to do its task.

Once I have ground a little past half way, I measure

things with a dial caliper. The reason I grind slightly past half

way is to make certain that the cutter will have the clearances

necessary to do its task.

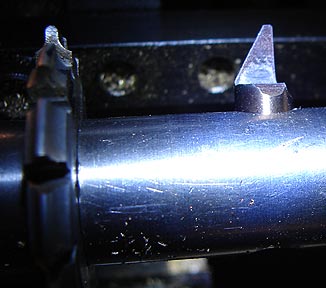

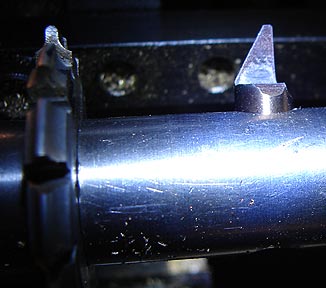

Here are several views. One side of the cutter is ground

at 0 degrees and the other at 30 degrees. The tip is ground with

a small flat. Notice that relief or clearance has been ground

on all faces of this cutter. That is a fingerprint on the center

picture not a crack in the HSS.

Here are several views. One side of the cutter is ground

at 0 degrees and the other at 30 degrees. The tip is ground with

a small flat. Notice that relief or clearance has been ground

on all faces of this cutter. That is a fingerprint on the center

picture not a crack in the HSS.

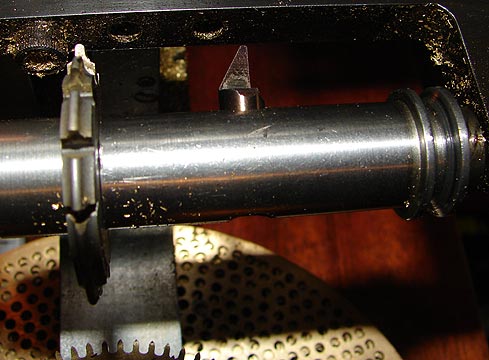

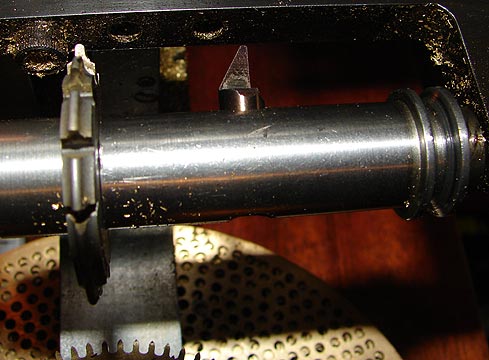

This is the finished cutter after grinding it off of

the rest of the bar.

This is the finished cutter after grinding it off of

the rest of the bar.  This new cutter gets mounted in the arbor of the wheel

engine cutter frame. You can see how it compares in profile to

the gear cutter.

This new cutter gets mounted in the arbor of the wheel

engine cutter frame. You can see how it compares in profile to

the gear cutter.

Here all of the

necessary relief angles are shown. These are critical.

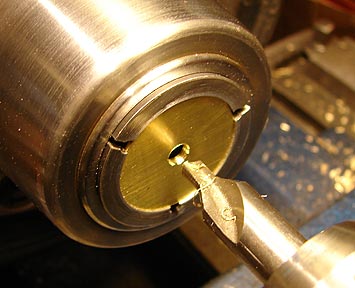

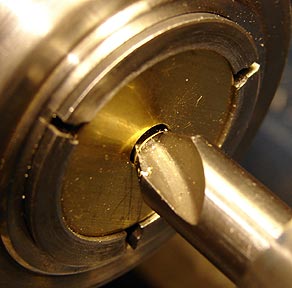

These are the brass blanks for the brake wheels to

be cut with the new fly cutter.

Here all of the

necessary relief angles are shown. These are critical.

These are the brass blanks for the brake wheels to

be cut with the new fly cutter.  These brass blanks are center drilled in the same manner

as the previous blanks. A new pot collet was used for them.

These brass blanks are center drilled in the same manner

as the previous blanks. A new pot collet was used for them.

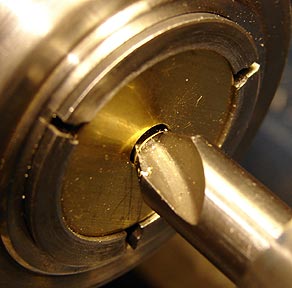

The

brake wheel blanks with their arbor holes.

Every other hole in the 70 tooth ring was used for

cutting the brake wheel.

The

brake wheel blanks with their arbor holes.

Every other hole in the 70 tooth ring was used for

cutting the brake wheel.

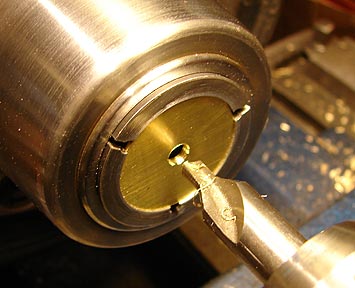

The blanks are

cut one wheel at a time using the fly cutter.

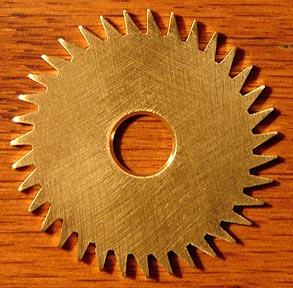

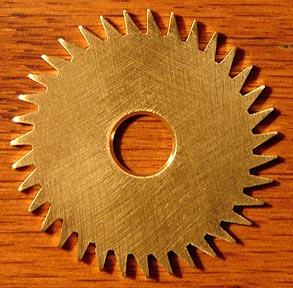

A completed brake wheel looks like this. It has 35

teeth.

The blanks are

cut one wheel at a time using the fly cutter.

A completed brake wheel looks like this. It has 35

teeth.

Here is a size

comparison of the three wheels made so far.

Click here to go to page 3

Click here to go to page 5

Here is a size

comparison of the three wheels made so far.

Click here to go to page 3

Click here to go to page 5

I make my fly cutters

out of 1/4" diameter HSS drill blanks.

I make my fly cutters

out of 1/4" diameter HSS drill blanks.

Here all of the

necessary relief angles are shown. These are critical.

Here all of the

necessary relief angles are shown. These are critical.

The

brake wheel blanks with their arbor holes.

The

brake wheel blanks with their arbor holes.

The blanks are

cut one wheel at a time using the fly cutter.

The blanks are

cut one wheel at a time using the fly cutter.

Here is a size

comparison of the three wheels made so far.

Here is a size

comparison of the three wheels made so far.